The above knowledge was instrumental in developing a solution as it allowed concepts and ideas to be adapted based on evidence. For example, an early concept solution was a special coating on the window to stop metal vapour adhering to it, like anti-fog coatings on glasses. Without detailed knowledge of the problem, it would be easy to think this is a complete solution. However, with more detailed knowledge we can immediately spot that this does not solve the spatter problem as no coating can both stop a flying spatter and be extremely transparent to IR radiation.

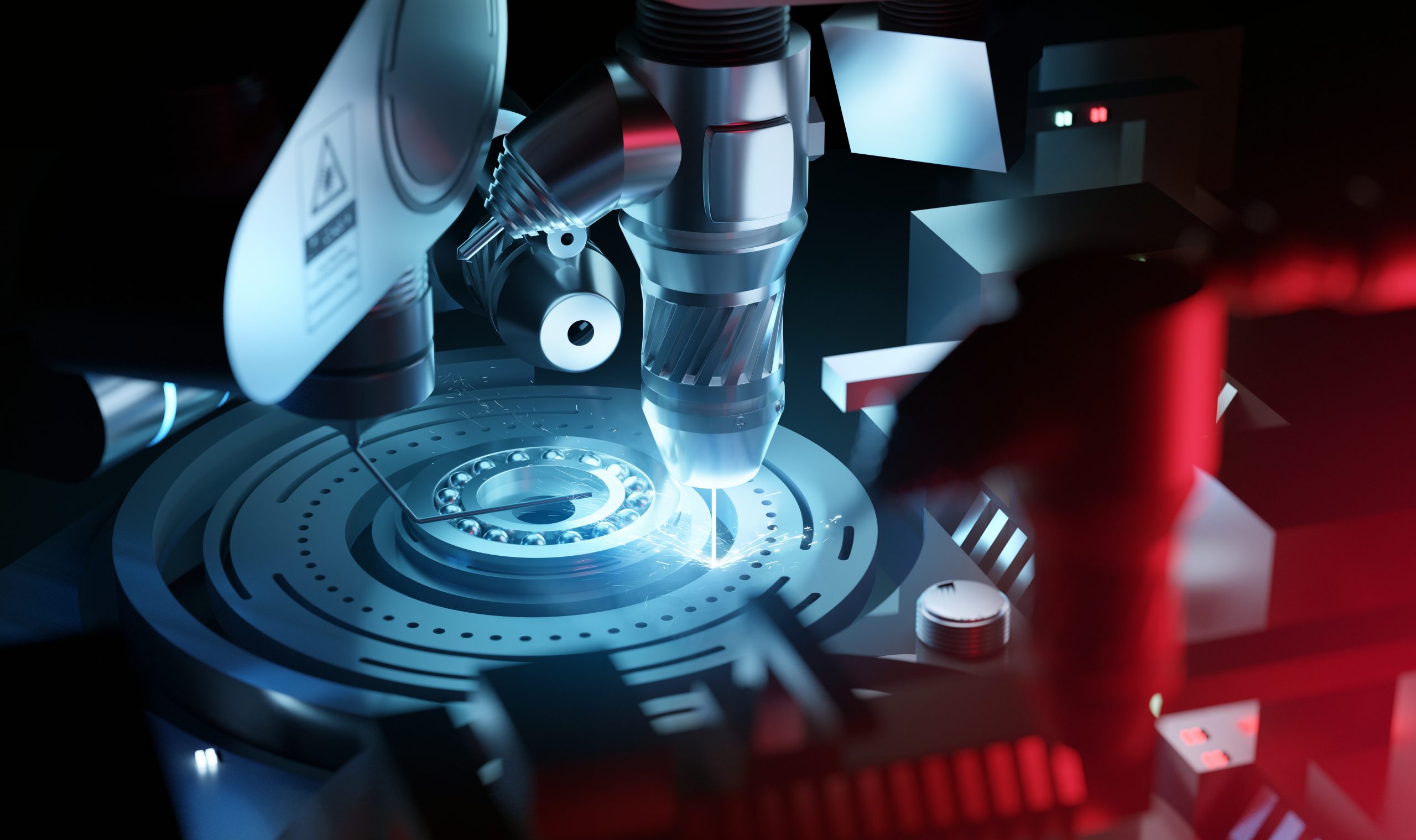

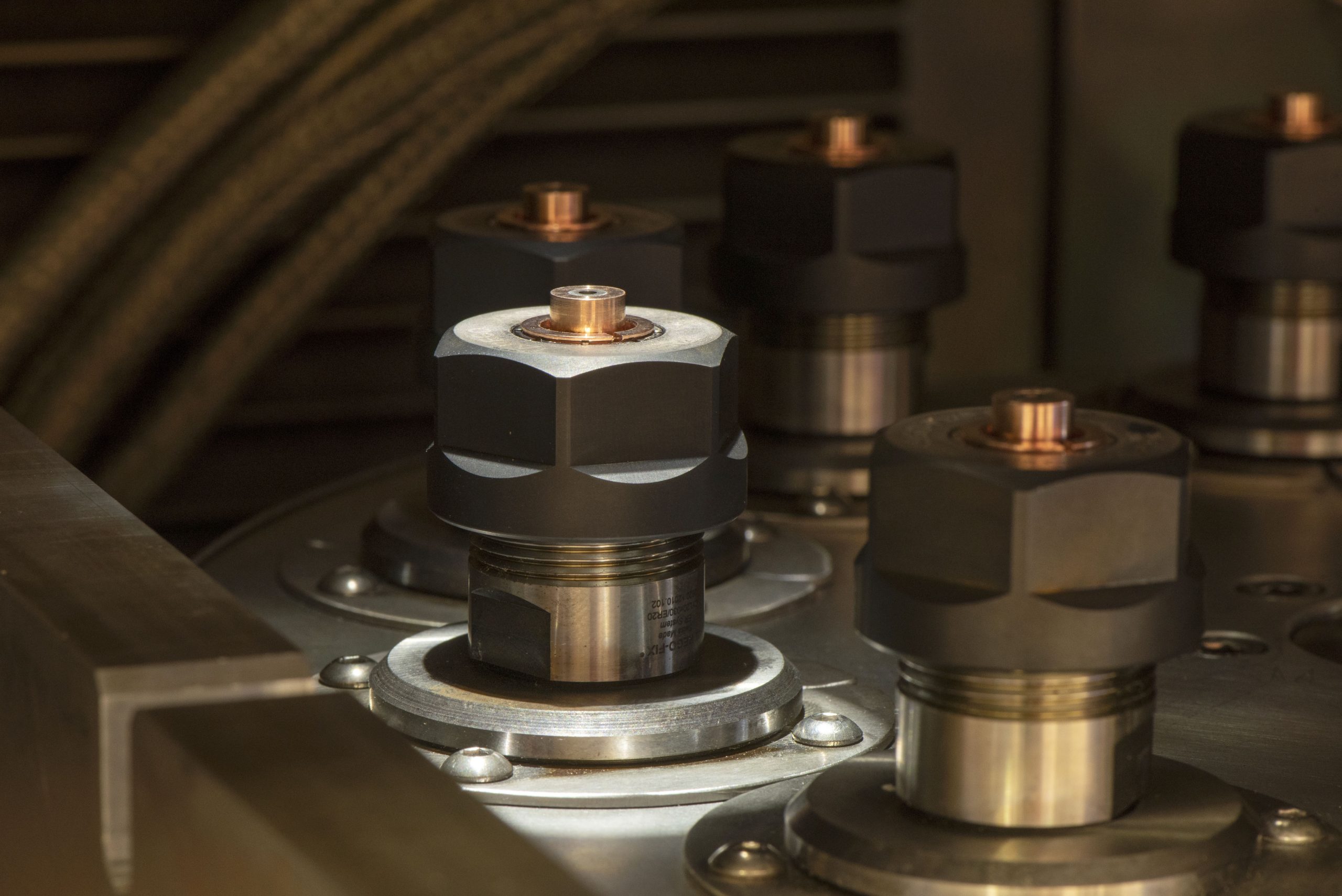

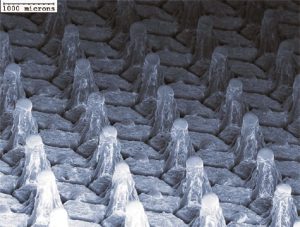

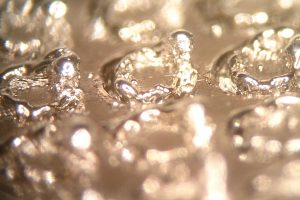

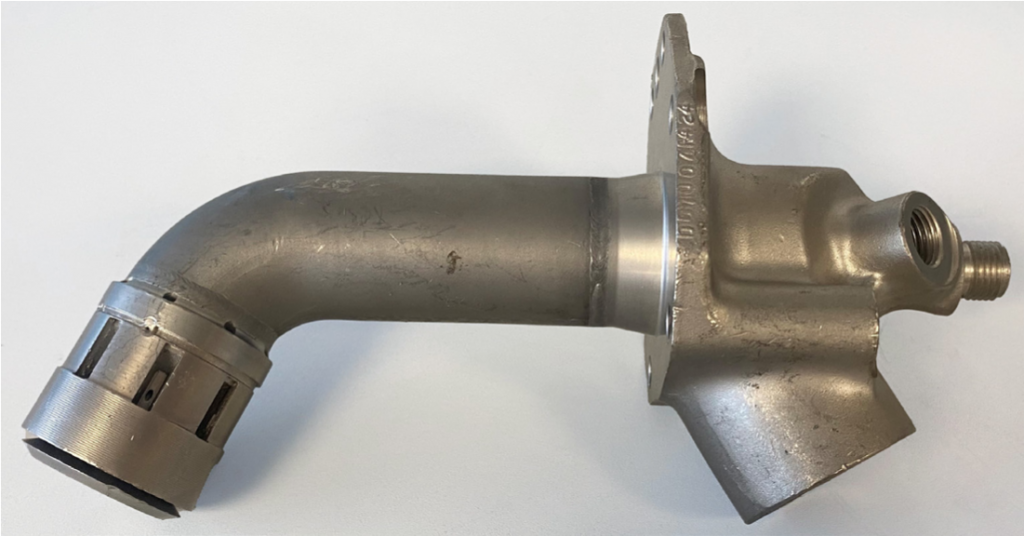

The first window protection system prototype, while effective at protecting the laser window for a time, caused a significant secondary problem: soot generation. This has been covered in some detail in our previous post so head over there to read more on the subject. To combat the soot generation problem, an entirely new solution was required, and armed with the knowledge of the window contamination problem and the soot problem, it was developed and tested. The new solution avoids the soot problem and produces long window lifetimes on the order of hours at medium powers. Simultaneously, a window exchange system was designed for rapid change-over of laser windows. The long window lifetime and short exchange time allow the LiV process to compete with EB’s comparable tungsten filament change process, a key milestone in commercialisation of the technology.

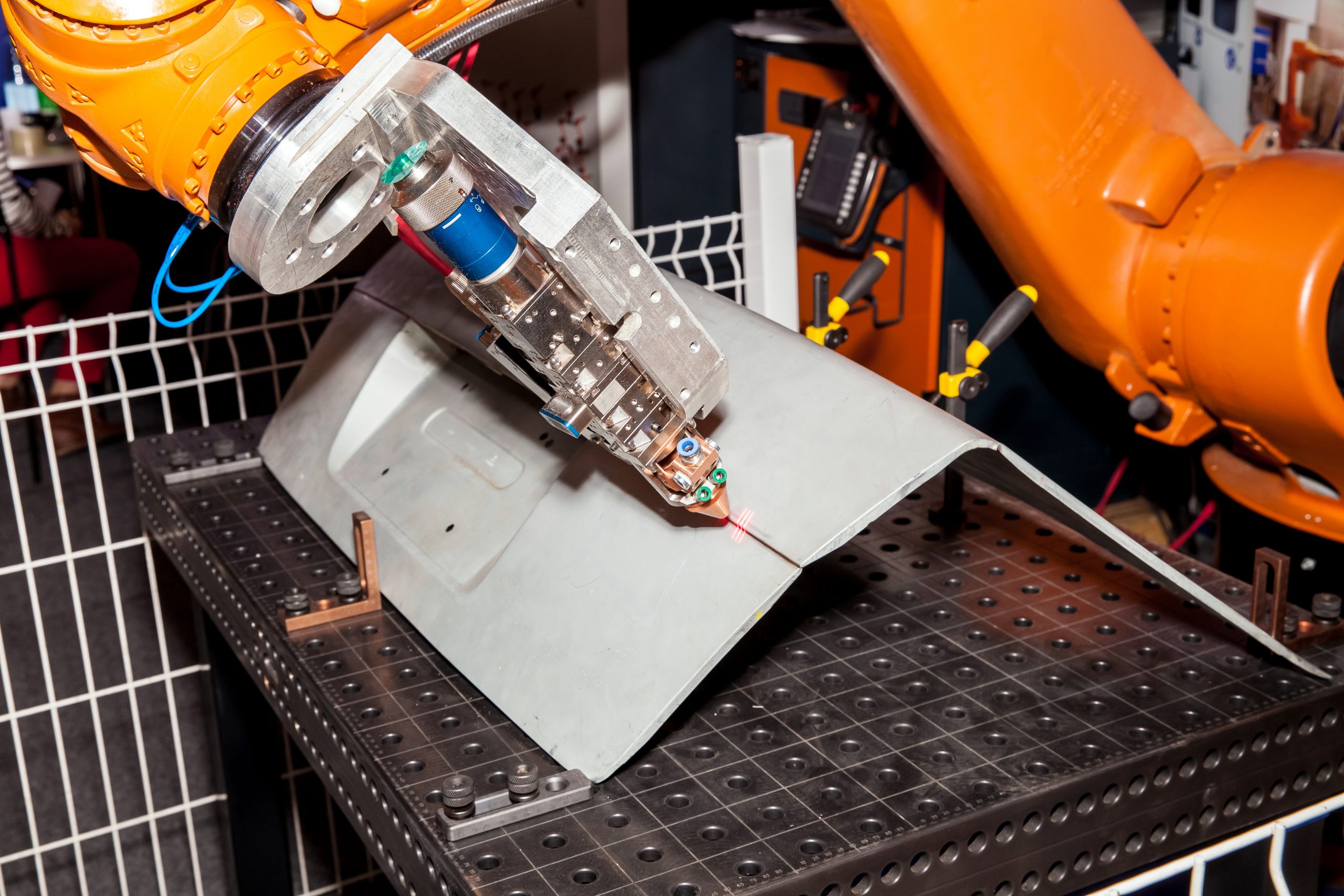

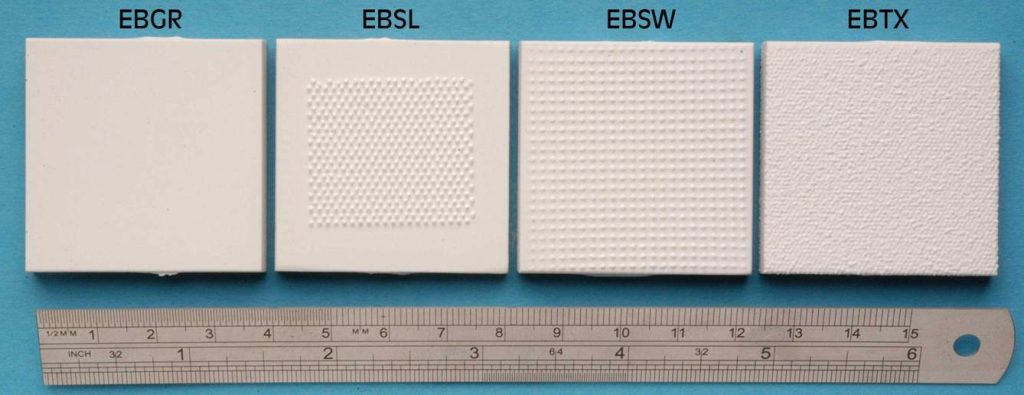

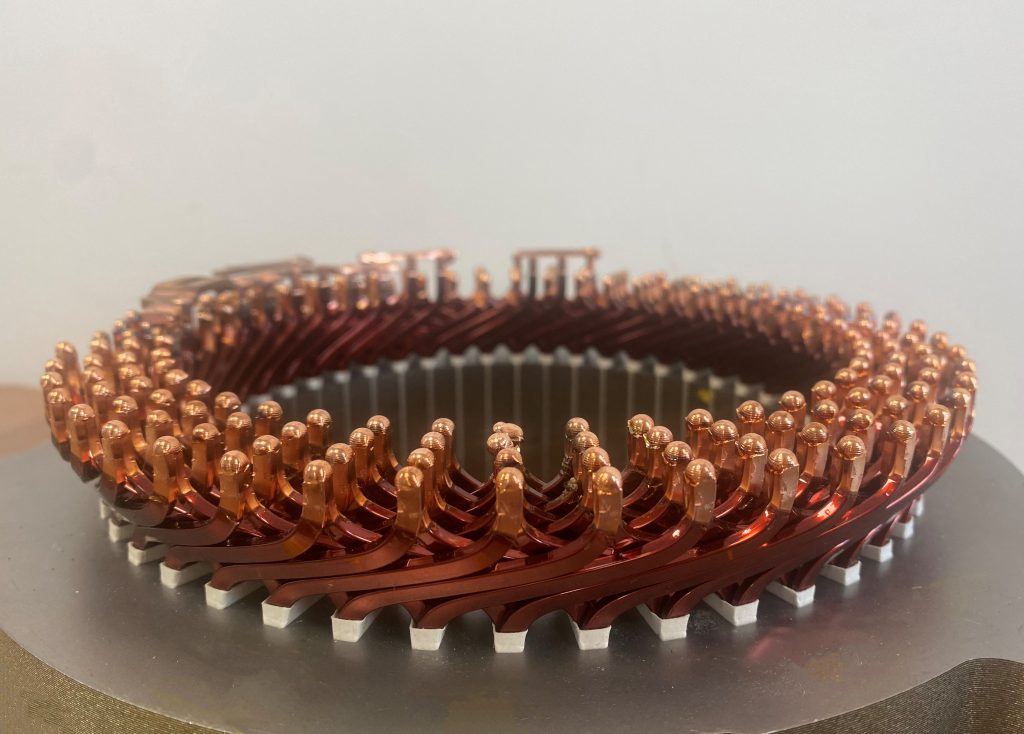

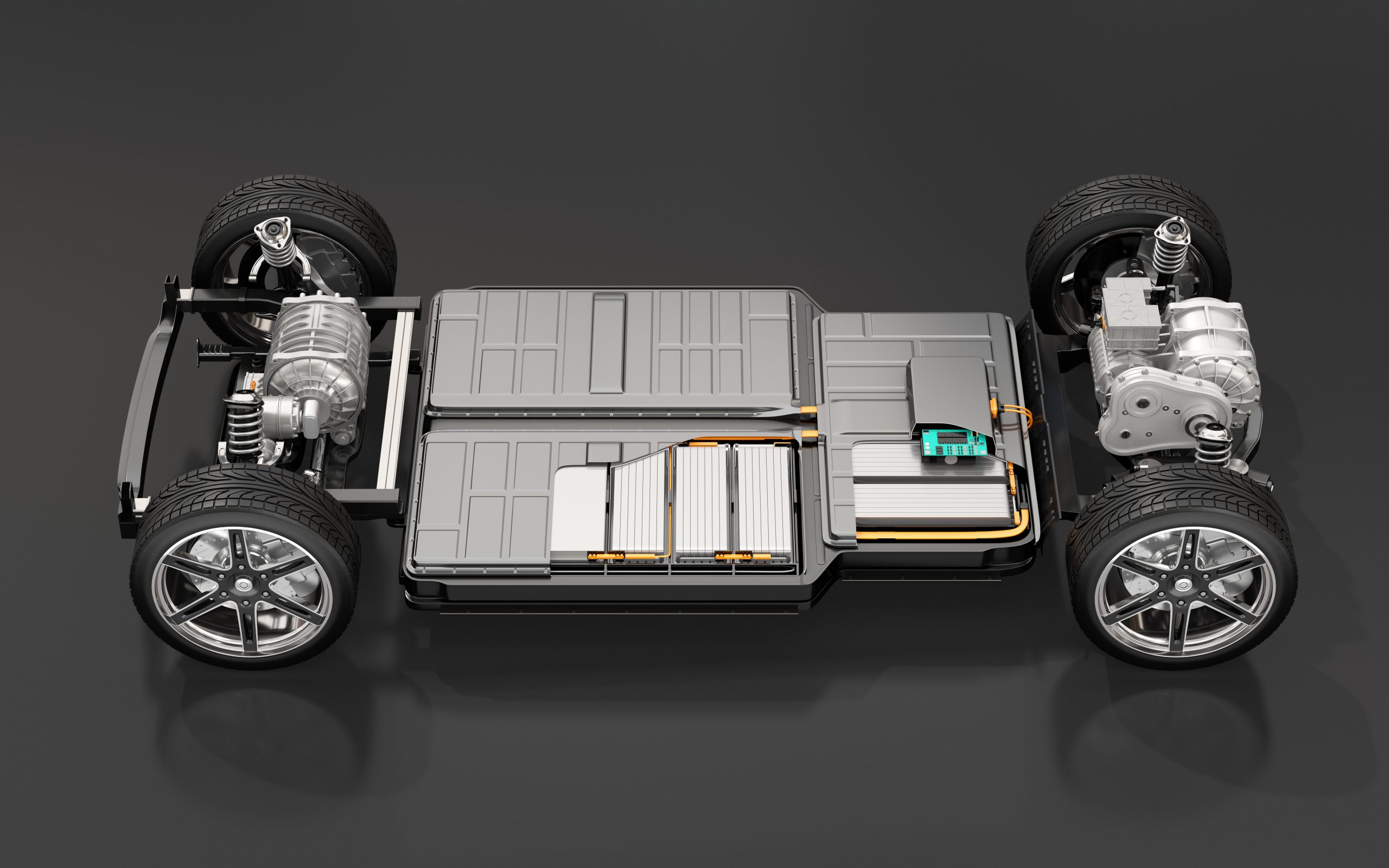

With the window problem solved for many common applications, the team now turned its focus to applications testing for different industries. Laser in vacuum has seen some high-quality academic research focusing on its applicability to specific industries, and academic institutes, end users, and manufacturers across the globe have conducted their own testing. All that said, LiV welding currently has low market penetration, though ever more organisations are beginning to see its benefits over their current process of choice (be it EB, standard laser, or even multi-pass SAW). Due to this currently low uptake rate and the sheer number of possible uses for the technology, most have not been tested. Of these applications, especially processes where EB is the incumbent, most do not need extensive testing to produce welds matching or exceeding the required quality. This is due to the stability and robustness of the LiV process, with welds being defect-free as standard, and the similarities in weld profile between EB and LiV.

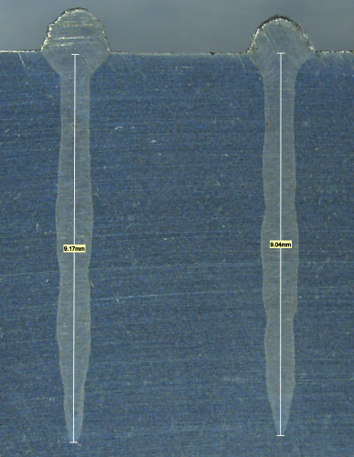

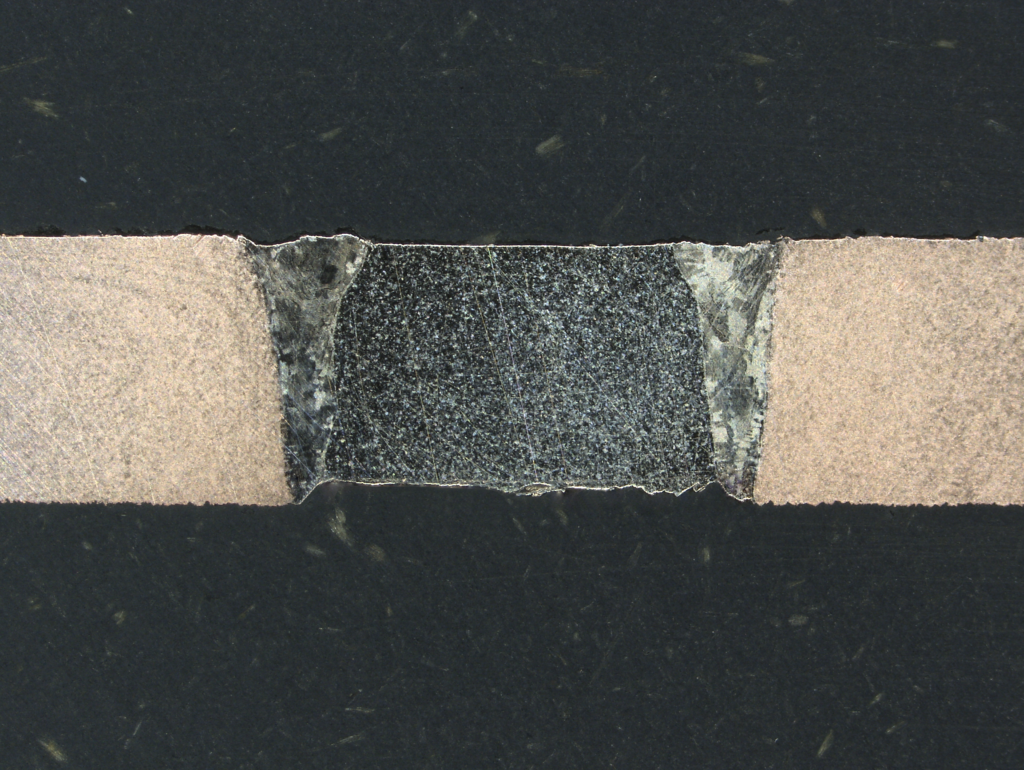

The applications testing performed has ranged from very shallow sub-mm to over 30mm penetration welds. The process of translating variable process parameters (speed, power, oscillation, spot size etc.) into weld features conforming to specific requirements (minimum/maximum weld height/underfill, half-depth width, penetration depth, root radius etc.) is not always a simple one and can require significant process understanding. Fortunately, this understanding is built upon by each application tested and the partnership has now built a strong base of knowledge about the optimal ways to achieve desired results in a diverse range of applications.

Throughout the project, the team has been using every new development or piece of knowledge to benefit running client contracts and to provide new options for interested clients. With a strong base of technical process knowledge and proven solutions to previously critical challenges, the partnership is now working to realise the potential of this powerful new tool in the joiner’s arsenal.