A Bit About Us

Specialists

Customer-focused

Leaders

Professional

Global

Highlighted Industries

Aerospace

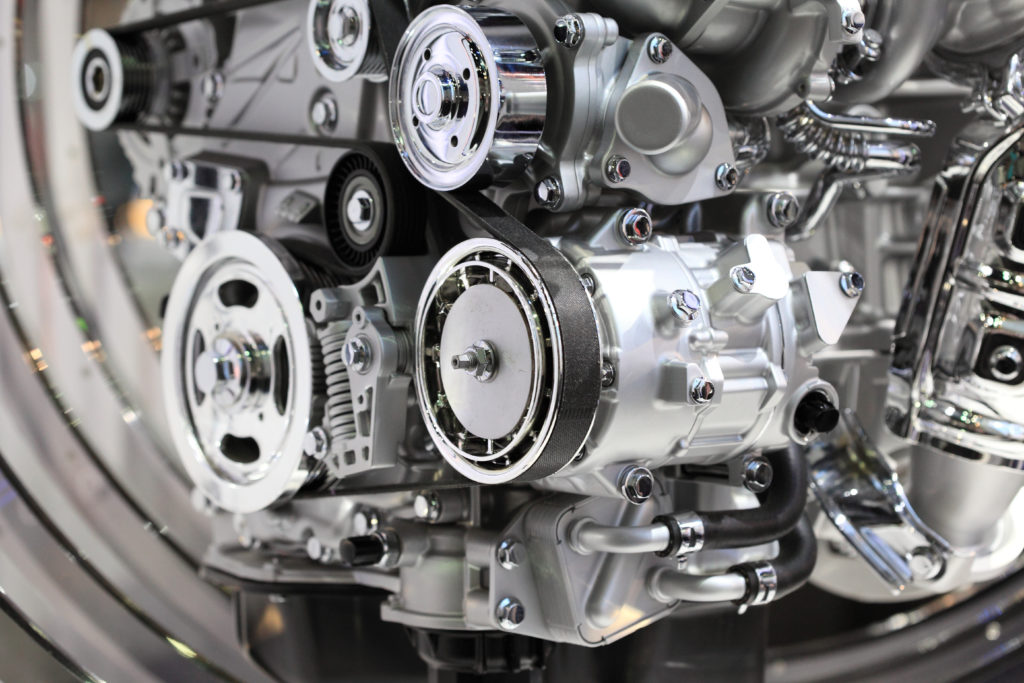

Automotive

Renewable Energy

Nuclear

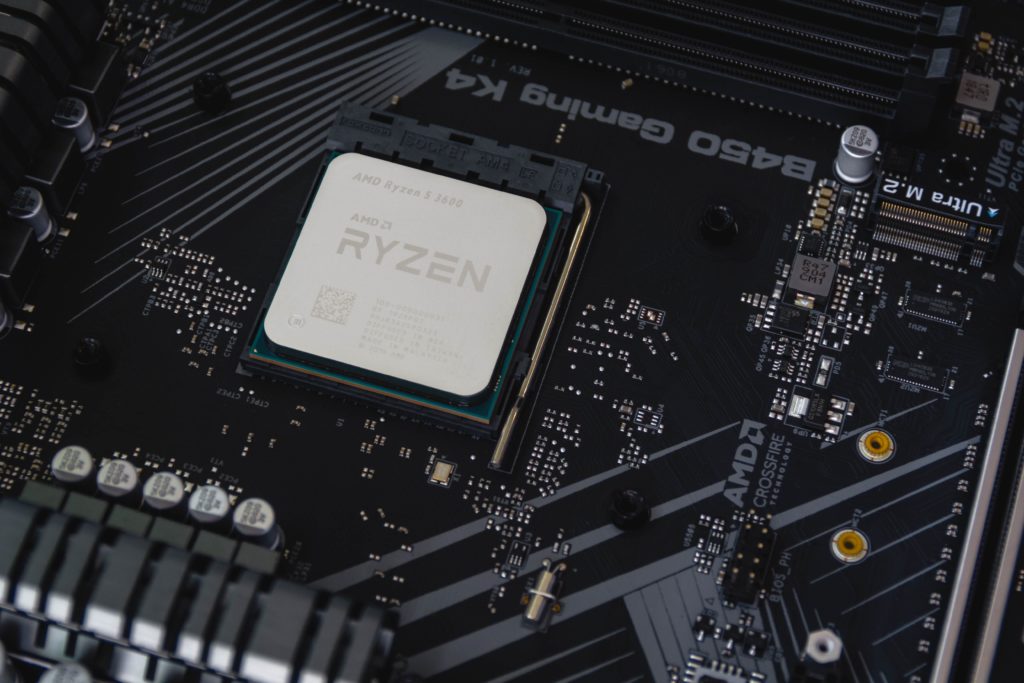

Electronics

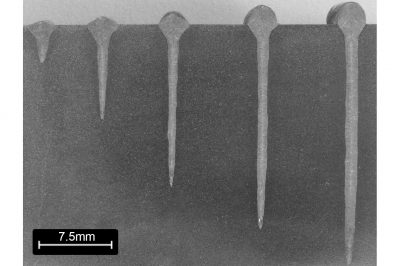

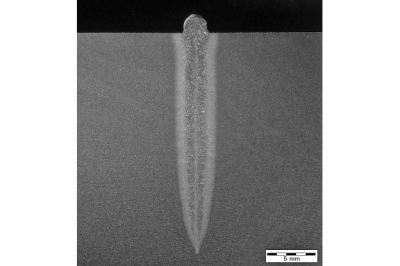

In the aerospace industry, electron beam welding can produce welds in a wide range of materials including titanium alloys, aluminium alloys, heat-resisting and high-strength alloys and can be successfully applied to high critical components, ensuring that stringent safety requirements are met.

In the automotive industry, electron beam welding has many applications; from turbochargers to gears and convertors to shunt resistors in standard fuel, hybrid, and electric vehicles. CVE can provide continuous strip welding systems for EV batteries, as well as turbocharger welders.

All offshore wind structures require high productivity welding fabrication and reliable performance. There is a range of structures that need to be fabricated as part of an offshore wind turbine, including monopiles, suction anchors, and flanges – and CVE can provide welding systems to achieve this.

There are many applications for electron beam welding in the nuclear industry, including pressure vessels for conventional power, small modular reactor (SMR) and micro modular reactor (MMR) fabrication, as well as associated pressure retaining and structural components.

The electron beam welding process has a low heat input, the shape of the fusion zone can be optimised and the process is done in a vacuum, which prevents oxidation, minimising the risk of damage to sensitive electronics.

News and Media

CVE and Ford improve production of electric motor stators

Electron beam welding proven to enhance stator manufacture as EV demand accelerates Cambridge Vacuum Engineering (CVE) and Ford have successfully completed a £430,000 Innovate UK-funded EB-eDrive project – proving that the manufacture of electric motor stators can be improved by utilising advanced electron beam welding. As part of Innovate UK’s Driving the Electric Revolution Challenge, […]