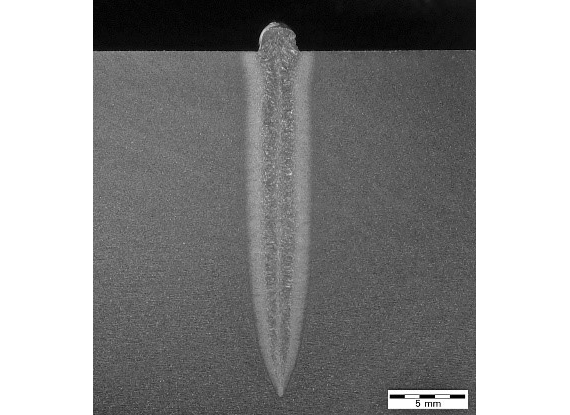

Weld Characteristics

The process presents the following characteristics:

- Deep, narrow weld

- Excellent mechanical properties

- High speed, high productivity

- Low distortion

- Minimal post-weld machining

- Suitable for thin section materials

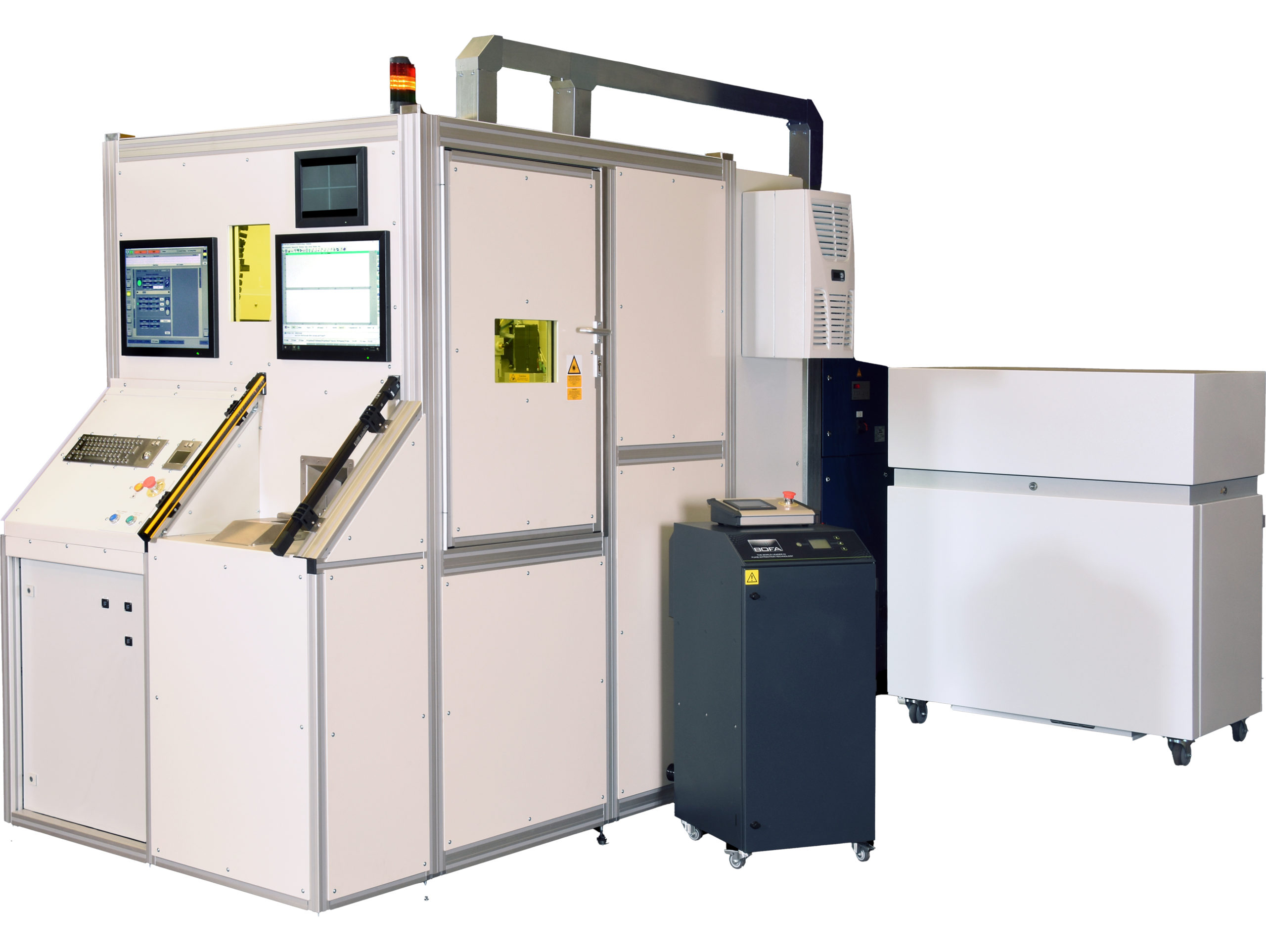

CVE's Laser Welding Machines

Please find our full range of machine models below.

CVE has completed a thorough programme of development work over the past few years surrounding laser, developing systems for welding in a protective atmosphere, in a vacuum chamber and with a local vacuum.

If you are not sure which system is right for your application, please get in touch! Our machines are built-to-order and manufactured at our Cambridge Headquarters. With 60-years of process know-how in providing turn-key solutions, we find the right solution for your application.

CVE operates a Quality Management System that complies with the requirements of BS EN ISO 9001:2015.