Laser in Vacuum Welding Machines

Laser in vacuum (LiV) welding is a relatively new technique that has the advantage of two to three times the depth of weld compared to conventional laser welding with shielding gas. It also has the benefits of reduced oxidation and extremely high welding quality.

Increased Beam Penetration and Quality

Conventional laser welding at atmospheric pressure leads to a build-up of hot metal vapour above the keyhole. This vapour plume scatters and refocuses the laser beam and drags chunks of molten metal from the melt pool, forming spatters.

Laser welding in a vacuum eliminates the hot vapour plume, as it can now expand away from the keyhole vicinity much more quickly. This process leads to a higher laser coupling-in efficiency and minimises spatter.

The vacuum environment also reduces the temperature at which the metal boils – allowing for double to triple penetration depth.

The approximate 1000K drop in boiling point (depending on the material) allows for a significantly larger fraction of the beam’s energy to be expended in vaporising the material.

The vacuum surrounding the keyhole and melt pool allows for more effective degassing, and of course, does not contain any air to oxidise the workpiece.

This results in drastically reduced porosity and a completely oxidation-free weld bead.

Benefits of Laser Welding in Vacuum

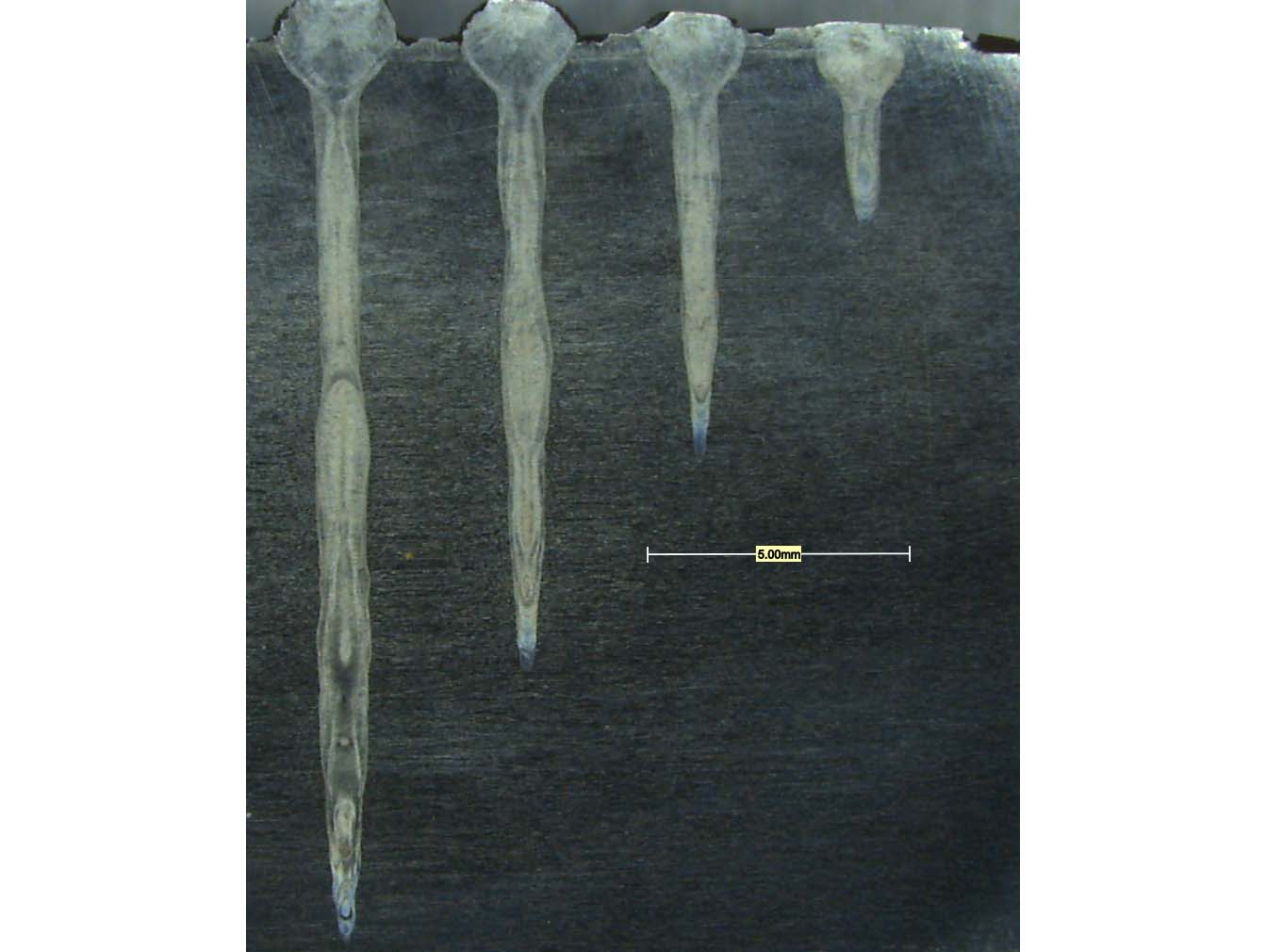

- An increase of over double the welding depth than in air

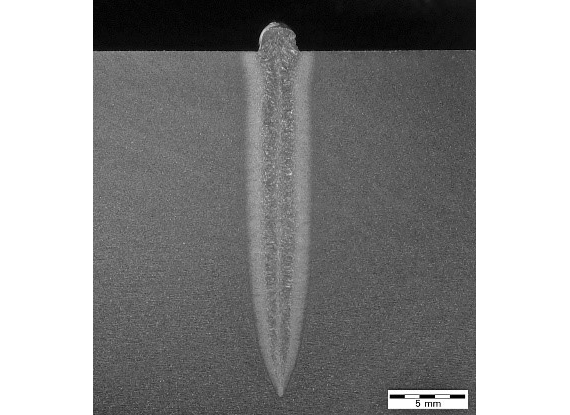

- Parallel-sided seams with reduced nailhead

- Increase process stability due to significantly reduced and stable plasma plume

- Reduction of workpiece contamination by spattering and vaporisation

- Higher-quality, pore-free weld seams

- Low operating costs due to efficient solid-state laser

- Welding process without inert gas

- No requirement for x-ray shielding

- Suitable for magnetic materials

Applications

The above features make vacuum laser welding a robust procedure to achieve high penetration welds.

Laser welding in a vacuum can also prove more flexible than electron beam welding in some applications due to the absence of X-rays and the avoidance of magnetism issues.

The application determines the choice between electron beam welding and laser in vacuum welding. For a detailed breakdown of the suitability of electron beam or laser for your application, why not contact us?

Gallery

A gallery of weld cross-sections, as well as CVE’s development system.