DEFENCE

Electron beam welding is a well-established welding process within the defence sector, due to the high-quality output that is required for the application. A variety of components ranging from small to large and simple to complex are welded on CVE electron beam welders.

Aluminium Alloys

High-strength aluminium alloys are commonly electron beam welded for applications such as missile cases, launchers, and armour piercing parts and in some instances, the mechanical properties are modified by the use of a wire feed system used during the welding process.

Small Components

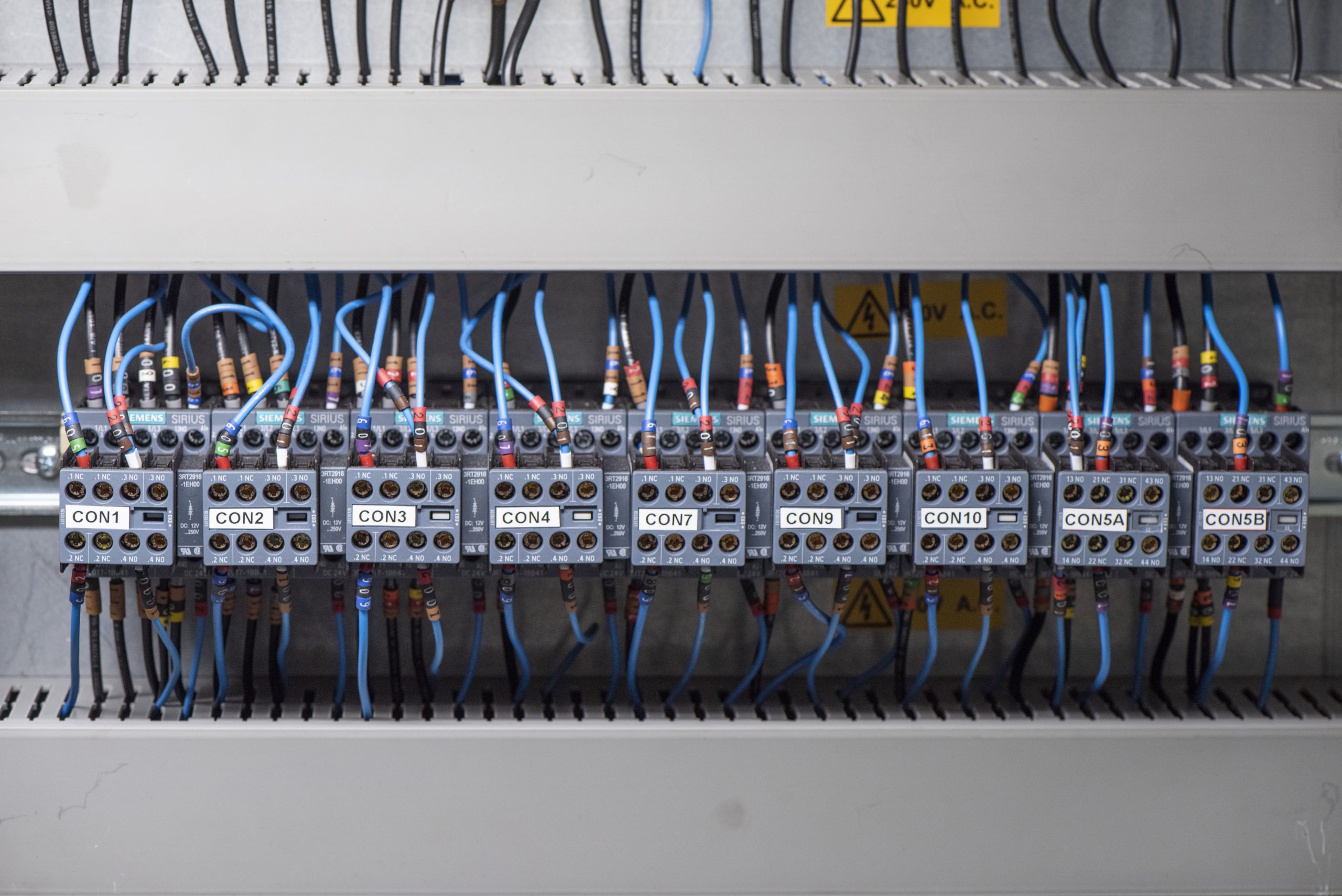

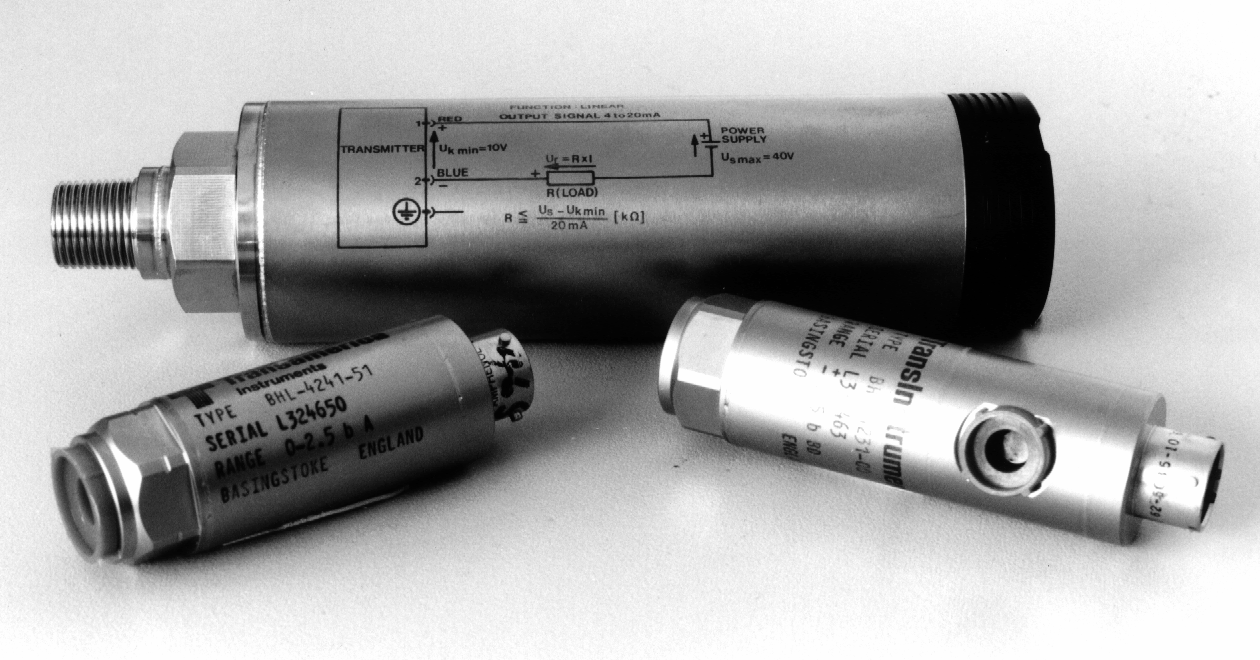

Transducers, relays, and aneroid capsules are examples of small components joined by electron beam welding in the defence sector.

Titanium Alloys

The high precision and 100% defect-free weld seams of electron beam welding are exploited for joining titanium alloys within the defence sector such as fuel propellant tanks and aero-engine rotors. Aero-engine parts are also commonly repaired, with electron beam used as the joining method.