Turbocharger Electron Beam Welding Machines

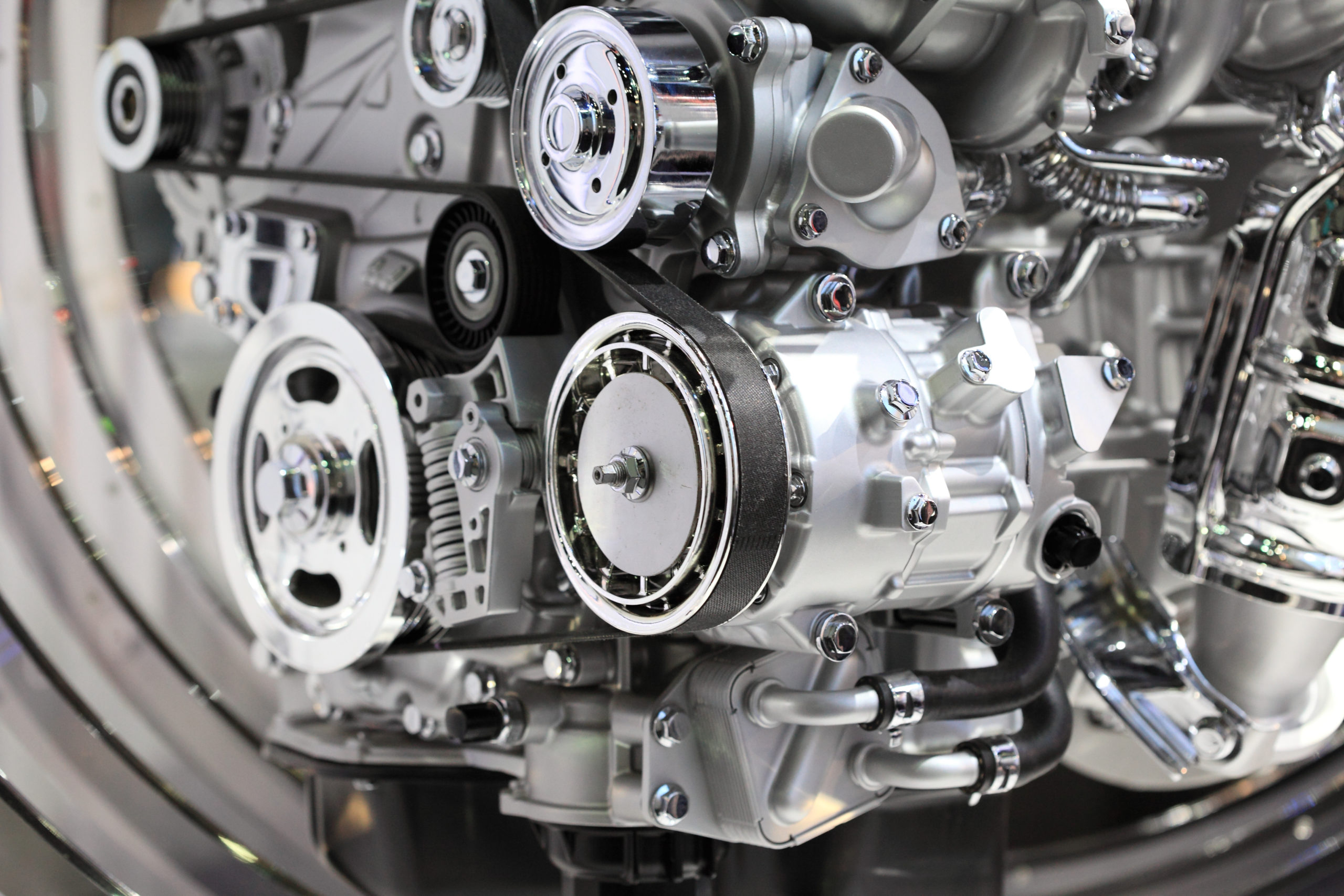

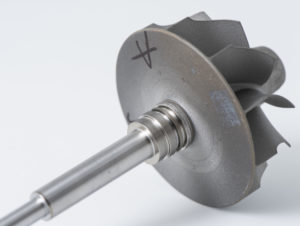

CVE’s turbocharger models have been designed specifically for turbochargers, an automotive component that is currently fitted in millions of vehicles across the world.

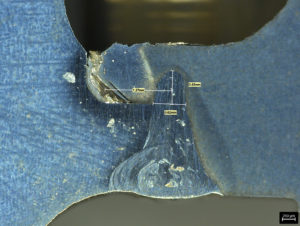

Electron beam welding joins a cast Inconel wheel and a carbon steel shaft together. The electron beam is a finely focused stream of electrons, which melts the two metal surfaces together, resulting in an excellent quality of weld with the characteristics of:

- Deep penetration

- Narrow fusion zone (HAZ)

- Near parent metal strength

Welding inside a vacuum environment ensures a clean and pure process.

Find out more about turbochargers.

TW Model

The TW model has a small footprint and high efficiency, and can accommodate manual or robot loading. The TW model is suitable for passenger car and commercial diesel applications. Find full details below or download the datasheet.

Specification

Standard Equipment

Advanced Features and Tooling Options

Gallery

| Typical takt time* | 30-35 s |

| Dual drive tooling housing

Maximum wheel size

|

A up to 53 mm

B 50-82 mm C 80-105 mm |

| Plain tooling housing | Up to 120 mm |

*Dependent on weld recipe, shaft diameter, and joint finding option

- Automatic beam alignment and filament heating

- Beam deflection patterns and function generator

- Ethernet hub for remote diagnostics

- High-quality HDMI camera and vision system

- HMI for recipe storage and data logging

- Industrial PLC with PC-based

- Separately pumped gun column

- Automatic joint finding option using back scattered electrons

- Directly heated cathode with high-intensity beam for low distortion

- Light guard protection of the loading area

- MES and industry 4.0 compatibility

- Plain tooling housing for self-aligning parts and dual drive tooling housing option for centring

- Pneumatic tailstock

- Quick change tooling

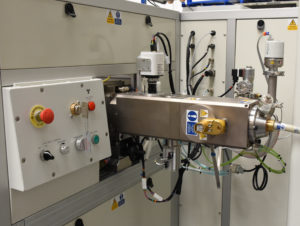

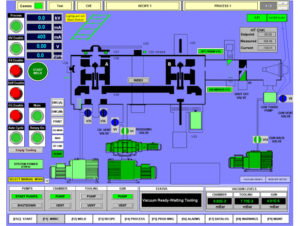

TW Model

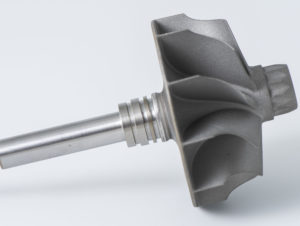

Turbocharger Component

D60LN gun column with filament alignment system and turbo-molecular pump

PC-based HMI with data log to hard drive and remote diagnostics via ethernet hub

NG Model

The NG model has a small footprint and high efficiency, and can accommodate manual or robot loading. The NG model is suitable for passenger car and commercial diesel applications. Find full details below or download the datasheet.

Specification

Standard Equipment

Advanced Features and Tooling Options

Gallery

| Typical takt time* | 20-22 s |

| Dual drive tooling housing

Maximum wheel size |

Up to 53 mm

|

| Plain tooling housing | Up to 65 mm |

*Dependent on weld recipe, shaft diameter, and joint finding option

- Automatic beam alignment and filament heating

- Beam deflection patterns and function generator

- Ethernet hub for remote diagnostics

- High-quality HDMI camera and vision system

- HMI for recipe storage and data logging

- Industrial PLC with PC-based

- Separately pumped gun column

- Automatic joint finding option using back scattered electrons

- Directly heated cathode with high-intensity beam for low distortion

- Light guard protection of the loading area

- MES and industry 4.0 compatibility

- Plain tooling housing for self-aligning parts and dual drive tooling housing option for centring

- Pneumatic tailstock

- Quick change tooling

NG Model

Shaft and Wheel

Tooling Housing

Weld Profile

SP Model

The SP model has a small footprint and high efficiency, and can accommodate manual or robot loading. The SP model is suitable for passenger car and commercial diesel applications. Find full details below or download the datasheet.

Specification

Standard Equipment

Advanced Features and Tooling Options

Gallery

| Typical takt time* | 15-18 s |

| Dual drive tooling housing

Maximum wheel size |

Up to 53 mm

|

| Plain tooling housing | Up to 65 mm |

*Dependent on weld recipe, shaft diameter, and joint finding option

- Automatic beam alignment and filament heating

- Beam deflection patterns and function generator

- Ethernet hub for remote diagnostics

- High-quality HDMI camera and vision system

- HMI for recipe storage and data logging

- Industrial PLC with PC-based

- Separately pumped gun column

- Automatic joint finding option using back scattered electrons

- Directly heated cathode with high-intensity beam for low distortion

- Light guard protection of the loading area

- MES and industry 4.0 compatibility

- Plain tooling housing for self-aligning parts and dual drive tooling housing option for centring

- Pneumatic tailstock

- Quick change tooling

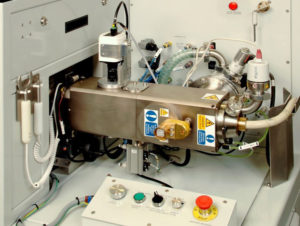

SP Model

Human Machine Interface

Tooling

Gun Column