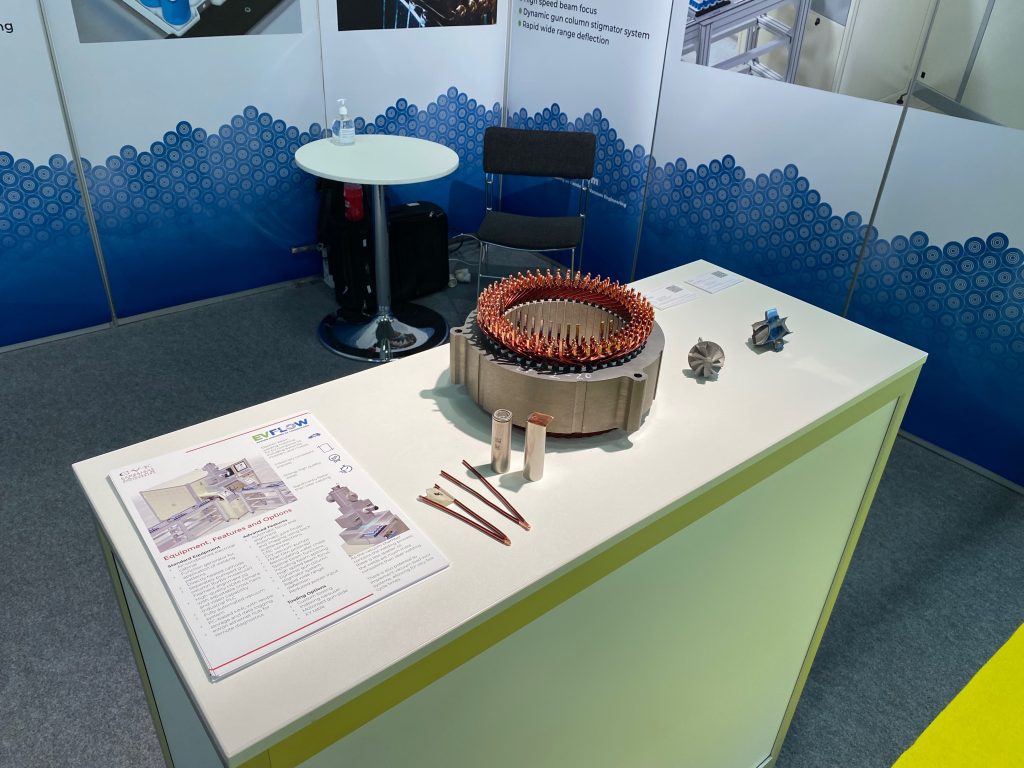

CVE Exhibit at Coil Winding CWIEME Event In Berlin

CWIEME Berlin

CVE are exhibiting at CWIEME in Berlin, 10-12 May 2022.

CWIEME is the Coil Winding, Insulation, Electronic Manufacturing Exhibition, which has the global coil winding, transformer, electric motor, generator, and e-mobility supply chain all in one place.

Meet the Team

On the stand you will find Chris Coaster (Sales Manager), Alex O’Farrell (Development Engineering Manager), Liam Howarth (Sales Agent), and Nick Edge (Consultant), who all look forward to meeting you!

To arrange a meeting in advance of attending the exhibition, please email sales@camvaceng.com.

Chris Coaster, Alex O’Farrell, Liam Howarth, and Nick Edge (left to right).

Find the Solution for Your Engineering Challenge

CWIEME is the the largest global event dedicated to the coil winding transformer, electric motor, generator and e-mobility supply chain, which enables global knowledge exchange.

Find the solutions to your latest engineering challenge among the over 600 leading components, raw material and process machinery manufacturers.

Product sectors include:

- Adhesives, resins, and coatings

- Electromechanical components

- Electronic and electrical components

- Electric powertrain components

- Insulation and shielding materials

- Intermediate semi-finished products and materials

- IT & software

- Motor components and accessories

- Other machines and manufacturing systems

- Transformer components and accessories

- Winding systems and supplies

For more information on the event, please visit the organiser’s website.