Electron Beam Welding for Aero Engine Applications

Introduction

The aero-engine industry has taken maximum advantage of the attributes of electron beam welding, the design of many components is based on its application.

The industry requires fabrications from various materials that are often difficult to weld by other methods such as forgings, pressings, or castings, often in a fully machined state. Although the finished fabrications may be complex, they will invariably be from relatively simple constituent parts. You can achieve lightweight yet rigid assemblies economically from the most appropriate materials.

You can perform electron beam welding reliably and repeatedly using established parameters and techniques that you can readily set up on a machine, even for small batches or one-off production.

Early Applications – Stator Blades

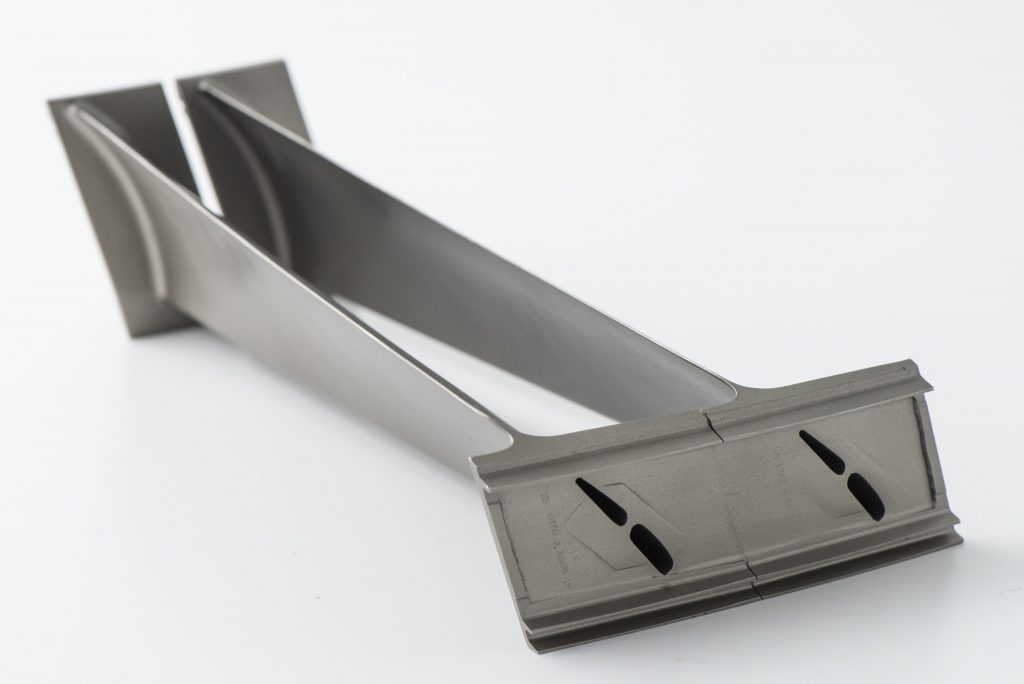

An early application within the aero engine industry was the welding of stator blades. The individual blades are cast in a range of steel or nickel-based alloys and are typically heat- and/or corrosion-resistant. The blade platforms also have varying sections, and there is a need to maintain close dimensional tolerances. Therefore, the range of joining methods that meet all criteria are strictly limited. The high-voltage beam of electrons is particularly successful in this type of application, where the thickness of the section may vary, yet throughout the progressive fusion, you can use the same weld parameters.

Fixtures are designed to accommodate several assemblies depending on component size. During the evacuation of the work chamber, the first joint is brought into view. As soon as the system reaches the correct pressure level, that joint is welded, and the X-Y table is indexed to the next joint. With several welds produced at each evacuation cycle, the total floor-to-floor time per weld may be less than 1 minute. Alternatively, a different approach would be to weld the complete ring in one evacuation cycle.

The welding procedure for each joint between blade platforms requires four weld passes: tack and finish weld for the outer platform, tack weld, and finish weld for the inner platform. Each weld pass requires a different set of beam settings and a different pattern of movement of the workpiece manipulator. Because of the complexity of the total weld programme, machines for this application incorporate teach-and-replay CNC, whereby the operator first teaches the system each of the subroutines for the four weld passes. He next teaches the system the angular position of each joint in a sequence that distributes the heat to minimise any possible distortion. From this point, the operator has only to initiate the welding cycle and for the machine to playback the complete sequence, with the operator taking on only a supervisory role.

Figure 1. Nickel-based alloy turbine blade.

Repair and Salvage

An equally important application for electron beam welding in the aero-engine industry is repair and salvage.

The general wear and tear on components within the arduous environment of the combustion gases, the strain on materials operating at high loads, often at high temperatures, create a continuous need for replacements.

High costs and long lead times are inevitable, but repair schemes can ensure a speedy, relatively low-cost turnaround of damaged or worn items. Because of the potential savings, most of the world’s airlines have installed their engine overhaul facilities and many of these incorporate electron beam welding. Repair schemes based on electron beam welding have approval for many components for both civil and military engines.

The welds are produced in a variety of materials and frequently in areas where access is limited. There is the added problem that, whilst in new parts, it is possible to ensure sufficient material to provide for any minor distortion; in repair work, you must base the scheme on the finished dimensions of the component you are repairing.

An interesting aspect of electron beam welding is its ability to weld together certain dissimilar metal combinations. This feature has been used within the industry to its advantage in several repair and salvage schemes where the added-on part has been produced in a material able to achieve a longer operational life than the original.

Figures 2 and 3. Nickel-based alloy turbine blade.