Clean Growth

The UK’s Clean Growth Strategy aims to cut greenhouse gas emissions and ensure affordable energy for businesses and consumers, as well as to increase productivity and protect the climate and environment.

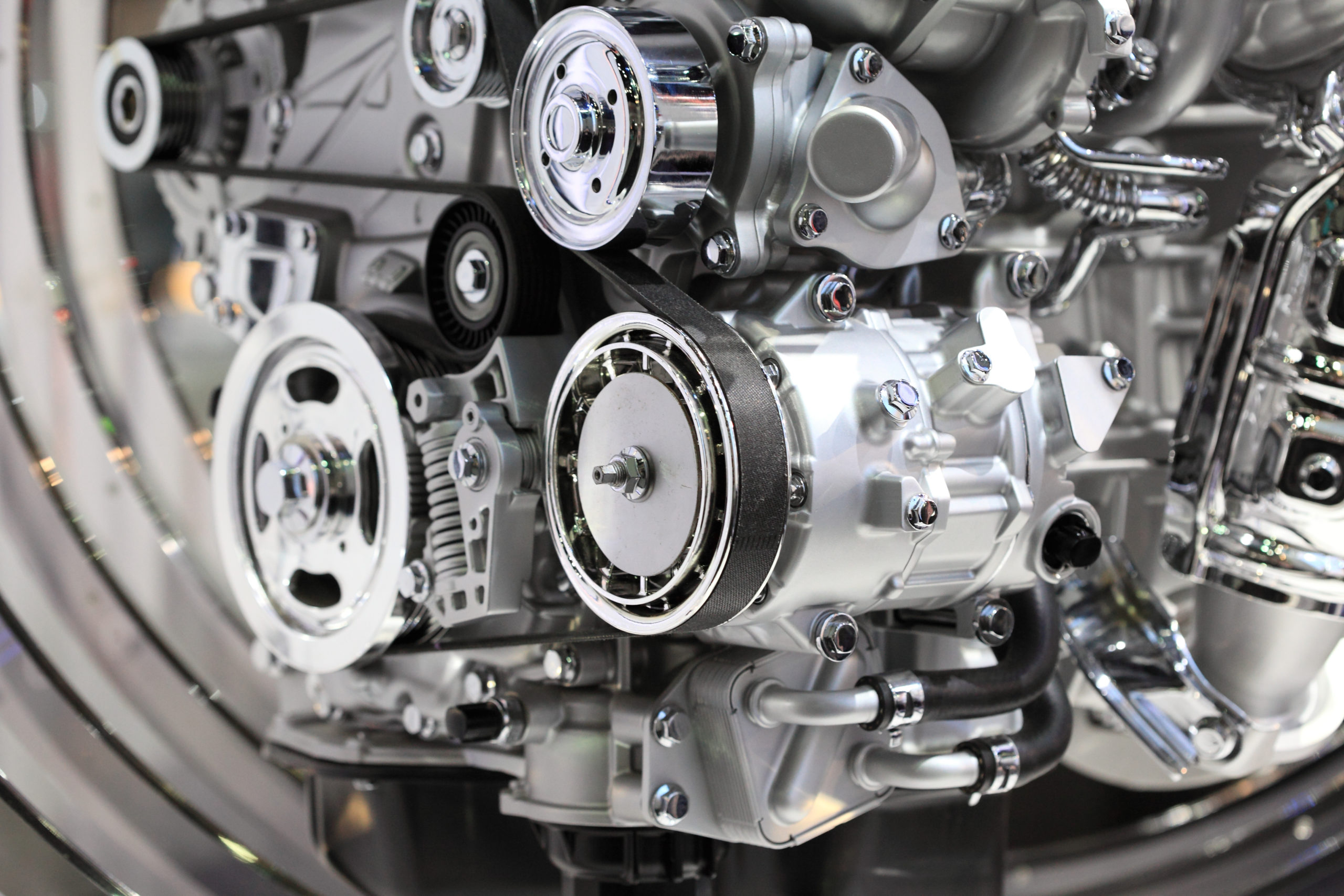

This includes increasing the production and use of zero and low-carbon energy, such as renewable and nuclear energy, and developing automotive engine technology to drive down emissions.

The UK aims to develop a new, technologically innovative, high-growth, low-carbon sector of the economy, and electron beam welding, Ebflow and Ebflow Light can play a crucial role within this development.

Find out how CVE have deployed electron beam and laser welding technology to relevant applications, underpinning the UK’s mission to achieve clean growth targets, by following the links below.

Ebflow

Renewable Energy

Additive Manufacturing

Additive manufacturing is the construction of a three-dimensional object and is commonly known as 3D printing. By using power beam systems, such as electron beam or laser, you can produce objects from powder or wire for higher deposition rates.

A variety of metals such as stainless steels, Inconel and titanium can be used in this layer additive process by melting the wire with the electron or laser beam and simultaneously manipulating the X, Y, and Z axes to produce a solid shape, which can later be machined to the final product.

ADVANCED TECHNOLOGIES

AEROSPACE

Industry 4.0

Industry 4.0 is the fourth industrial revolution, involving smart manufacturing and factories, cloud computing, big data, the internet of things (IoT), artificial intelligence and more.

Traceability is becoming increasingly popular and commonplace in production lines where you can extract data at each stage of manufacture. Many components have barcodes or data matrix codes on them that you can scan through the production process.

CVE can implement code scanners on machines allowing for the weld data, related to that specific component, that the client’s manufacturing execution system (MES) can extract.

Even without scanners, CVE machines log and store all weld related data which can be exported and analysed in multiple formats.

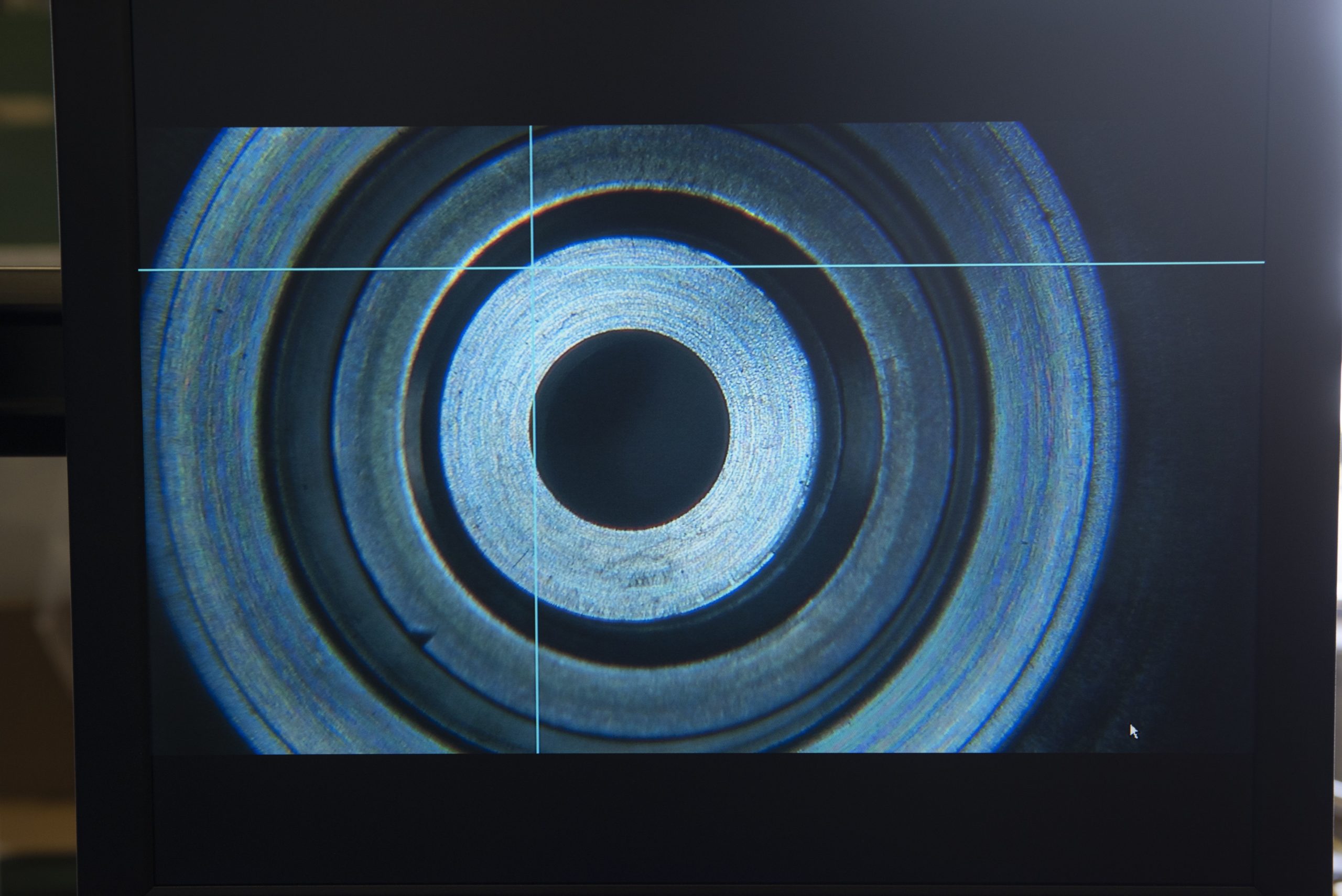

TURBOCHARGER MACHINES