Ebflow: Local Vacuum Electron Beam Welding System

High-productivity welding is an important factor influencing the economics of fabrication of large structures destined for use in the pressure vessel, offshore, and heavy engineering fabrication industries.

Electron beam welding is a process that offers significant benefits in terms of productivity increases, repeatability, and accuracy in the fabrication of large, heavy wall structures.

Ebflow is a local vacuum, electron beam welding system that you can readily transport and operate on-site and apply to significantly larger components than an in-chamber welder can accommodate. Therefore, Ebflow brings all the advantages of electron beam welding to steel structures of unlimited size (ferrous and non-ferrous, e.g. carbon steels, stainless steels, aluminium, titanium).

Ebflow is 20-30 times faster than conventional submerged arc welding. 200mm per minute in 150mm thick steel is achievable – allowing for the fastest thick-section rates ever.

For more information visit www.ebflow.com

Innovation and Design for an Effective Thick-section Welding Solution

Ebflow System Highlights

- A local vacuum is established and maintained only where it is needed

- You can perform post-weld inspection immediately

- Delivers increased weld quality and reliability, with low distortion

- Minimal weld prep/bevel required – ‘edge to edge’ fit-up

- Contributes towards significant improvements in carbon footprint, quality, economy, and productivity

- The sliding seals and precision handling systems enable fast set-up and pre-welding operations for a variety of workpiece dimensions

- Welding consumables are not required (no filler wire – autogenous)

- Welding without pre-heating is possible

How Does Ebflow Work?

A system of sliding seals and precision handling enables fast longitudinal and circumferential welds on large workpieces. A coarse vacuum is ideal for thick-section welding – achieving the fastest thick section welding rates ever.

There is no filler wire, so the weld is autogenous. As a result, it can be heat-treated, and the weld rendered metallurgically indistinguishable from the parent material.

Ebflow’s differential pumping and RF heated diode gun allow for operation in local vacuum pressure of c.1 mbar (high vacuum is 5×10-1 to 1×10-1 mbar).

There is precision handling on the head of the Ebflow system, and you can mount this flexibly, e.g. on circular tracks.

The system also has local seals around the welding head, which creates a coarse vacuum. CVE provide a box seal for the rear of the weld.

Fast longitudinal and circumferential welds are possible on large workpieces. The local vacuum nature of Ebflow is particularly suitable for large, tubular thick-section material.

For more information on how Ebflow works, download our technical brochure.

Industries and Applications

Ebflow is a versatile system with applications in a wide range of industries, from oil and gas to nuclear power generation to ship building and more.

Click through the slider to explore a summary of applications.

What are the Benefits of Ebflow?

Ebflow is 20-30 times faster than conventional arc welding, offering transformational gains in productivity.

It also uses less power than conventional arc welding processes, thereby lowering the carbon footprint.

Among the myriad of other benefits is the ability to perform low-heat input welds that result in reduced distortion – ensuring quality – and the option to perform NDT testing immediately after welding, fast-tracking the manufacturing process, and driving down costs. Other benefits include:

1. Reduced Carbon Footprint

The energy consumed in one metre of a weld is as much as 75% less using Ebflow than in standard submerged arc welding. In addition to this there is:

- Reduced transportation and installation costs

- No need for filler materials, chamber and associated pumping equipment

- No pre-heating

- No loading-unloading operations

2. Greater Productivity

Post weld heat treatment (PWHT) can create a weld rendered metallurgically indistinguishable from the parent material enabling welded components to be used in place of a single forging. Ebflow also contributes to other productivity gains by providing:

- A higher speed of manufacture

- On-site welding capability

- No requirement for weld joint bevel

- Flexibility to weld objects of any size

- No pre-heating requirement

- No loading, evacuation and unloading operations

- Possibility to immediately inspect post-weld

- Weld in a single-pass

3. Improved Economy

The energy consumed in one metre of a weld is 75% less using Ebflow than in the standard submerged arc welding (SAW) process. In addition to this, there are:

- Lower working capital requirements

- Lower personnel costs

- No chamber and associated pumping equipment

- Reduced transportation costs

- No filler materials – lower consumable costs

- Smaller factory footprint possible

4. Higher Quality

Ebflow delivers continuously repeatable and accurate high-quality welds, with localised residual stresses. The weld is rendered metallurgically indistinguishable from the parent material, whilst also having minimal distortion.

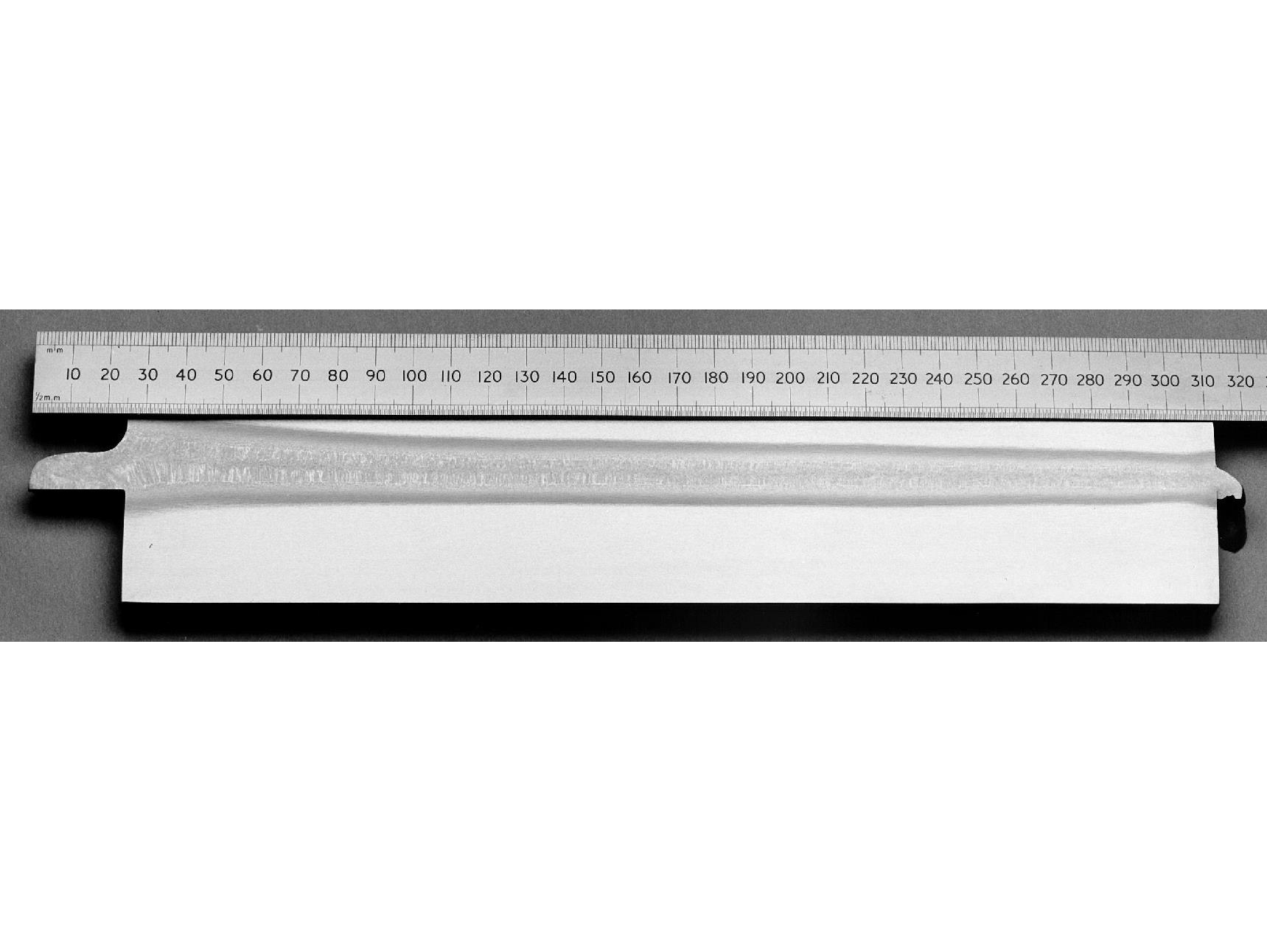

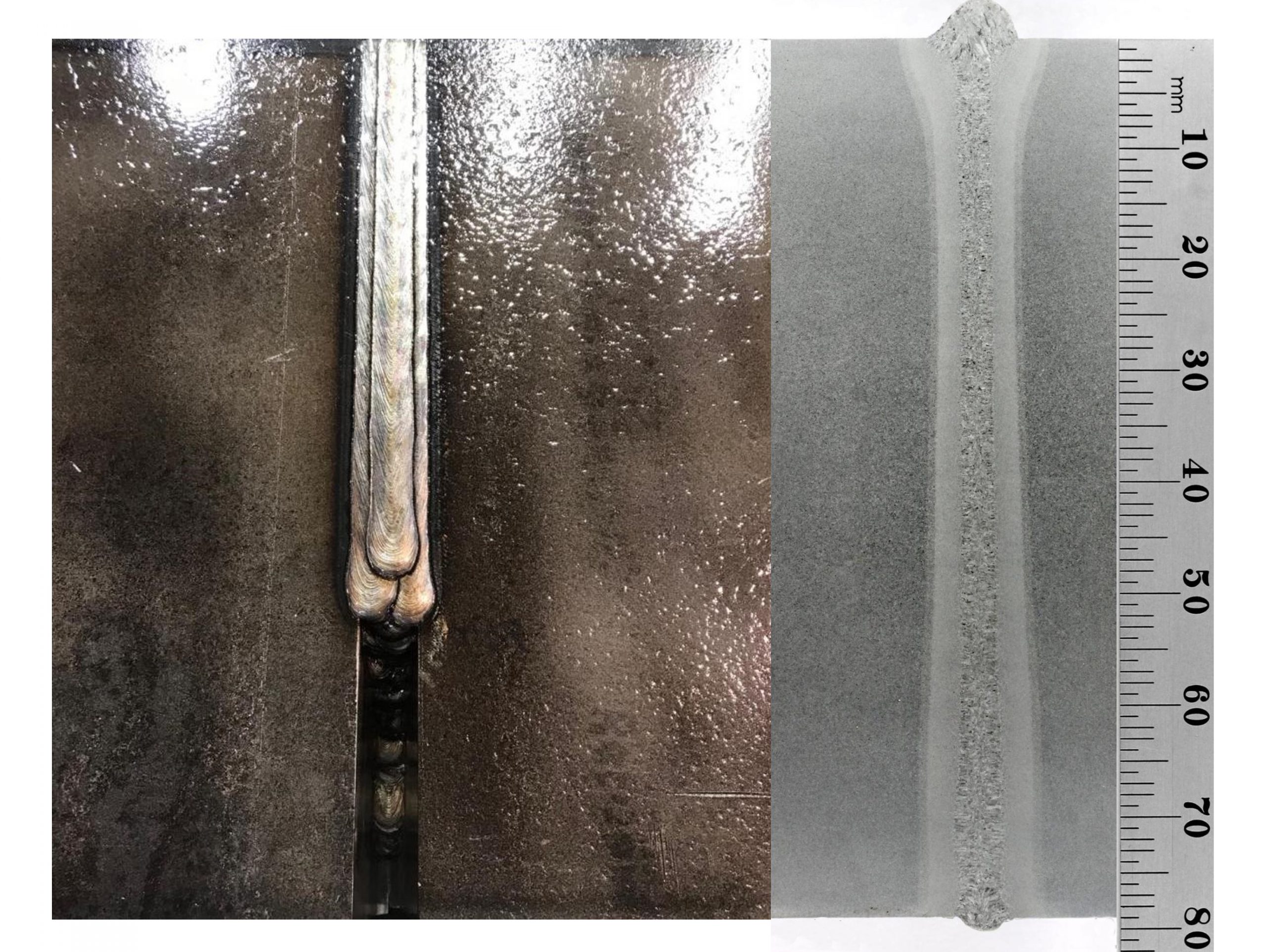

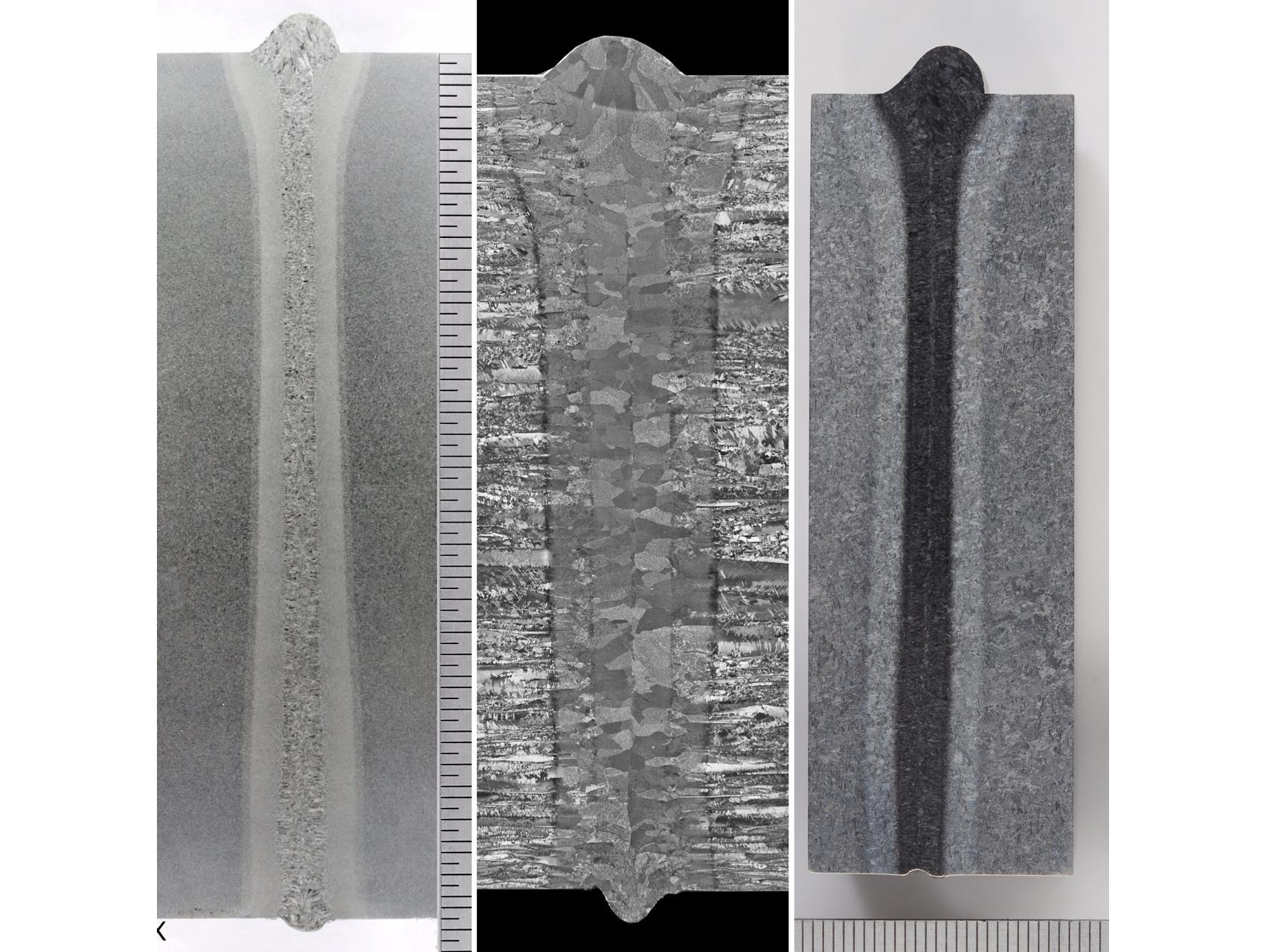

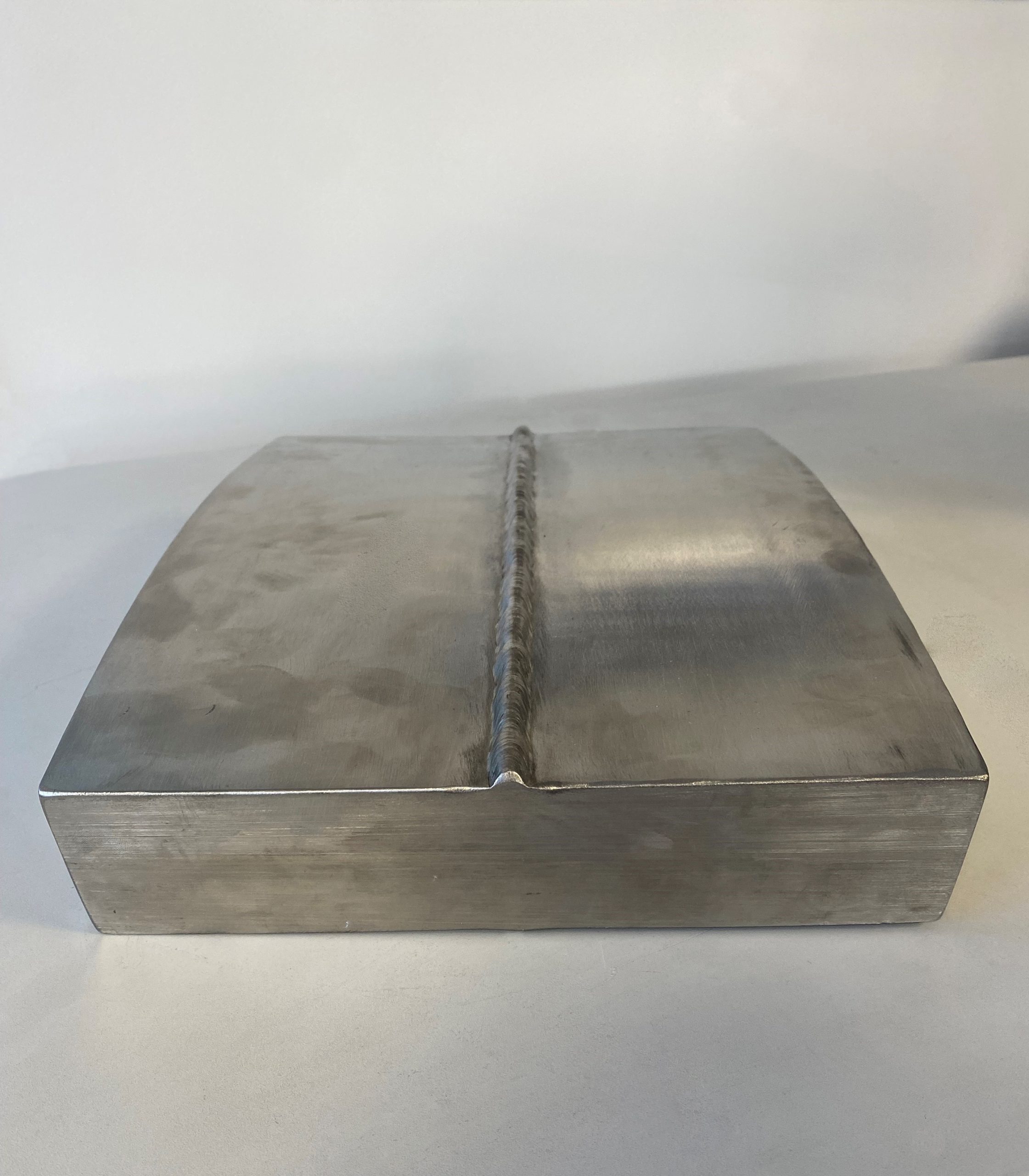

Gallery

Please take a look through the gallery below, which highlights weld cross-sections as well as images of systems installed on-site.