Applications of 60kV Systems

Introduction

CVE’s 60kV electron beam welding machine range is ideal for welding small-to-medium-sized components at high efficiency.

60kV machines are suitable for all metals including those with high thermal conductivity, such as:

- Steel and stainless steel

- Aluminium and its alloys

- Nickel alloys and refractory metals

- Titanium and its alloys

- Zr, Mo, Ta, Hf, W, Nb, etc.

The low heat input means that sensitive internal electronics packages may be sealed in the device without harm.

Please find a detailed list of industries and components below.

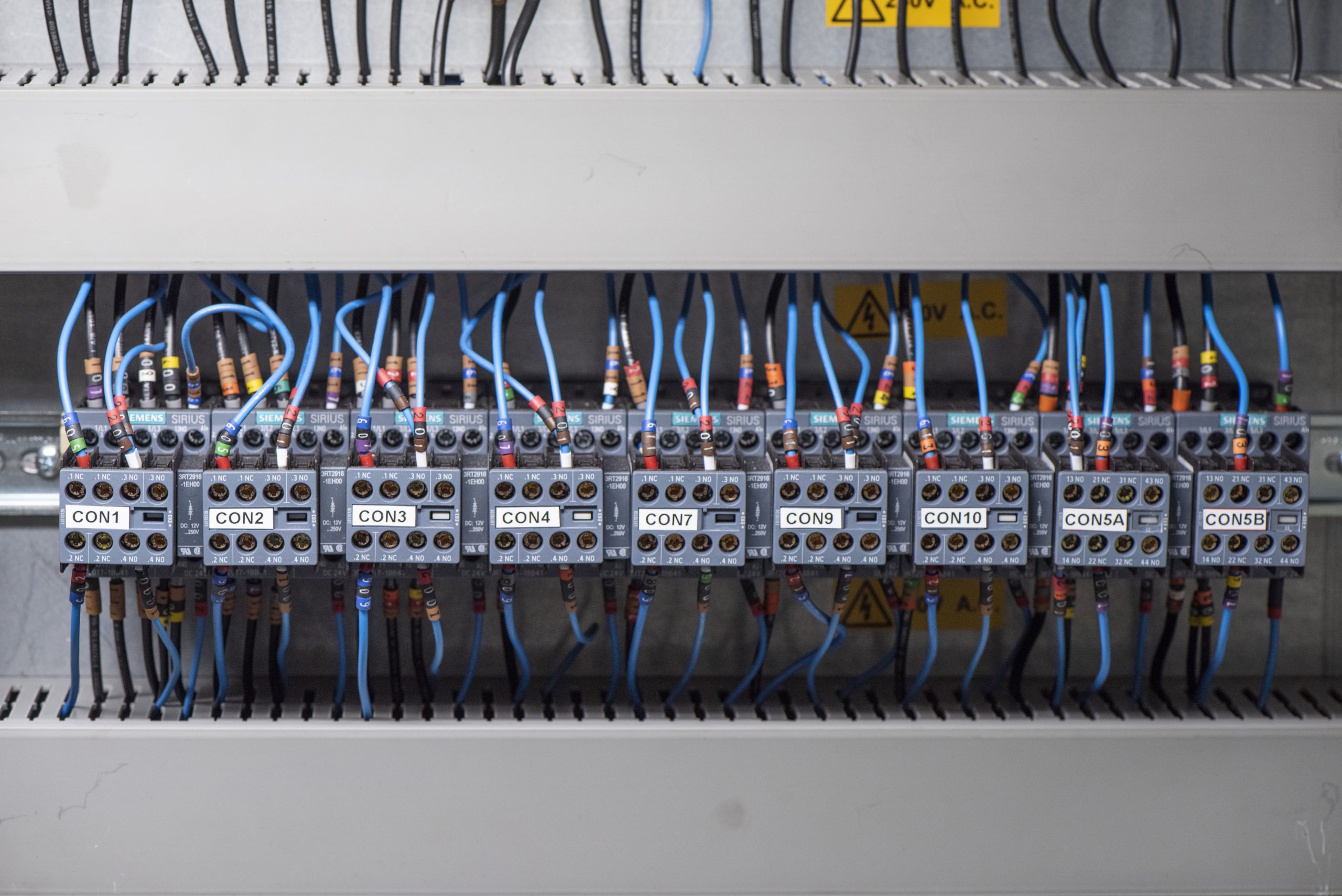

Aerospace

- Jet engine components (figure 1)

- Sensors and structures

- Transmission parts

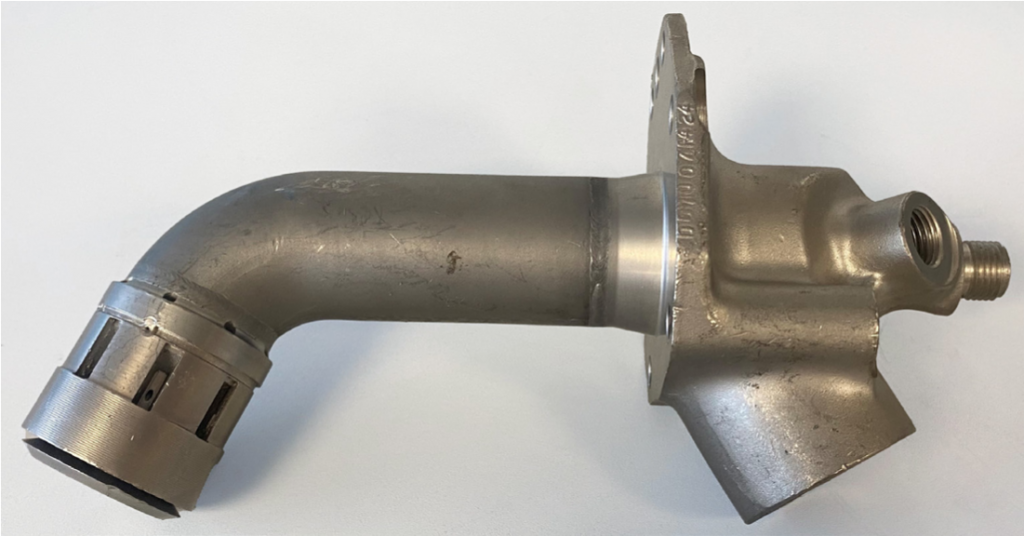

Automotive

- Gears

- Transmission parts

- Turbocharger parts (figure 2)

Figure 1. Nickel-based alloy fuel spray nozzle for an aero-engine.

Electronics

- Encapsulated electronics

- Heatsinks

- Parts in copper material

Medical

- Instruments

- Implants

- Surgical tools

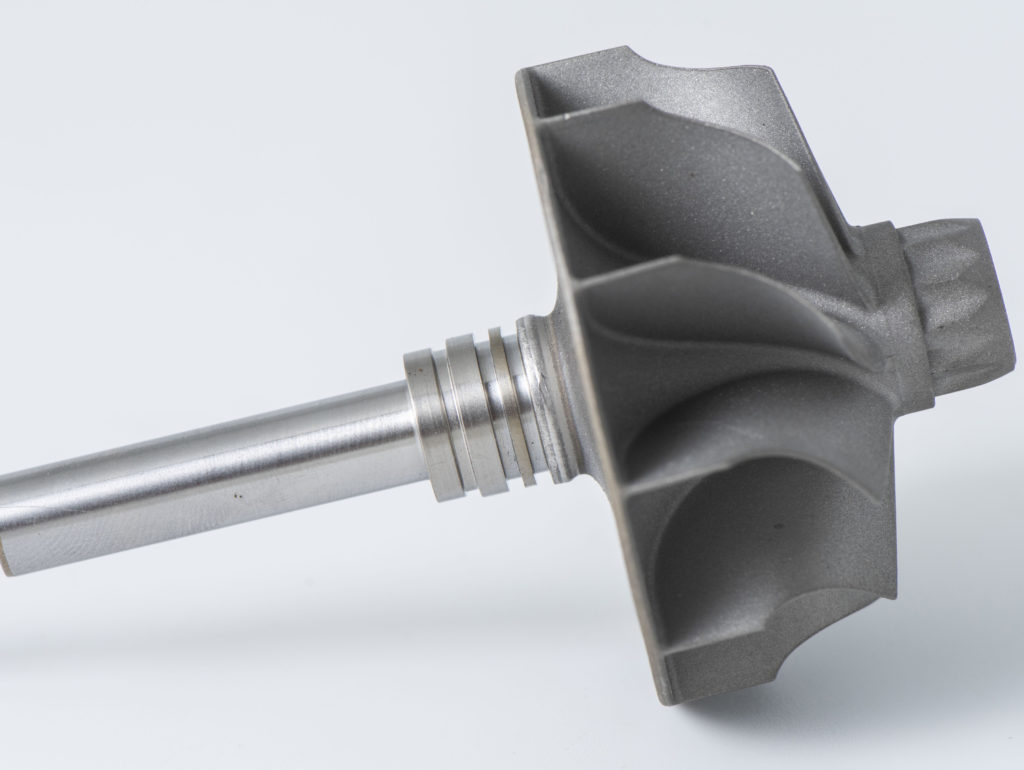

Nuclear

- Fuel housing

- Instrumentations

- Valves (figure 3)

Figure 2. Inconel, MAR and carbon-steel turbocharger shaft wheel assembly.

Power Generation

- Combustion chambers

- Sensors

- Vanes

Oil and Gas

- Mining tools

- Exploration sensors

- Valves

Semiconductor

- Heaters and plates

- Showerheads

- Surface modifications

Figure 3. Stainless steel valve body.

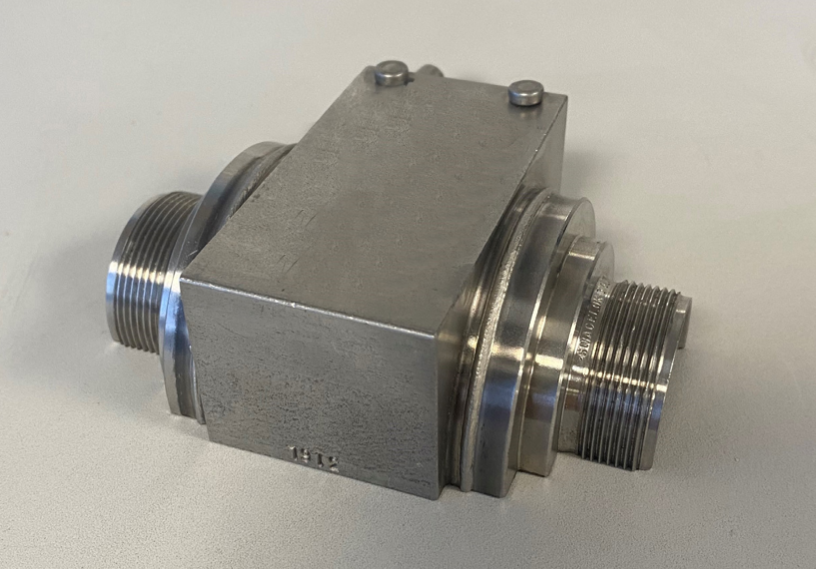

Space

- Sensors (figure 4)

- Titanium tanks

Vacuum Systems

- Chambers for drying or coating

- Thermal vacuum chambers

Welding of metals with dissimilar melting points

- Copper to steel

- Copper/steel to nickel alloys

- Steel to Inconel

- Tantalum to tungsten

Figure 4. Pressure sensor.

Machine Types

CVE have two 60kV machine types, ECO and CW.

The ECO model has a modular, flexible design to enhance production capabilities. The ECO is ideal for welding small-to-medium-sized components, with a small footprint and high-efficiency.

The CW model has a modular, flexible design to enhance production capabilities. The CW is ideal for the welding of medium-sized components and is suitable for thermally conductive materials.