Laser Welding Machines

Conventional laser beam welding is a process that typically occurs at atmospheric pressure, using a shielding gas.

Shield gasses are consumable and are often necessary to protect the weld area from oxygen and water vapour.

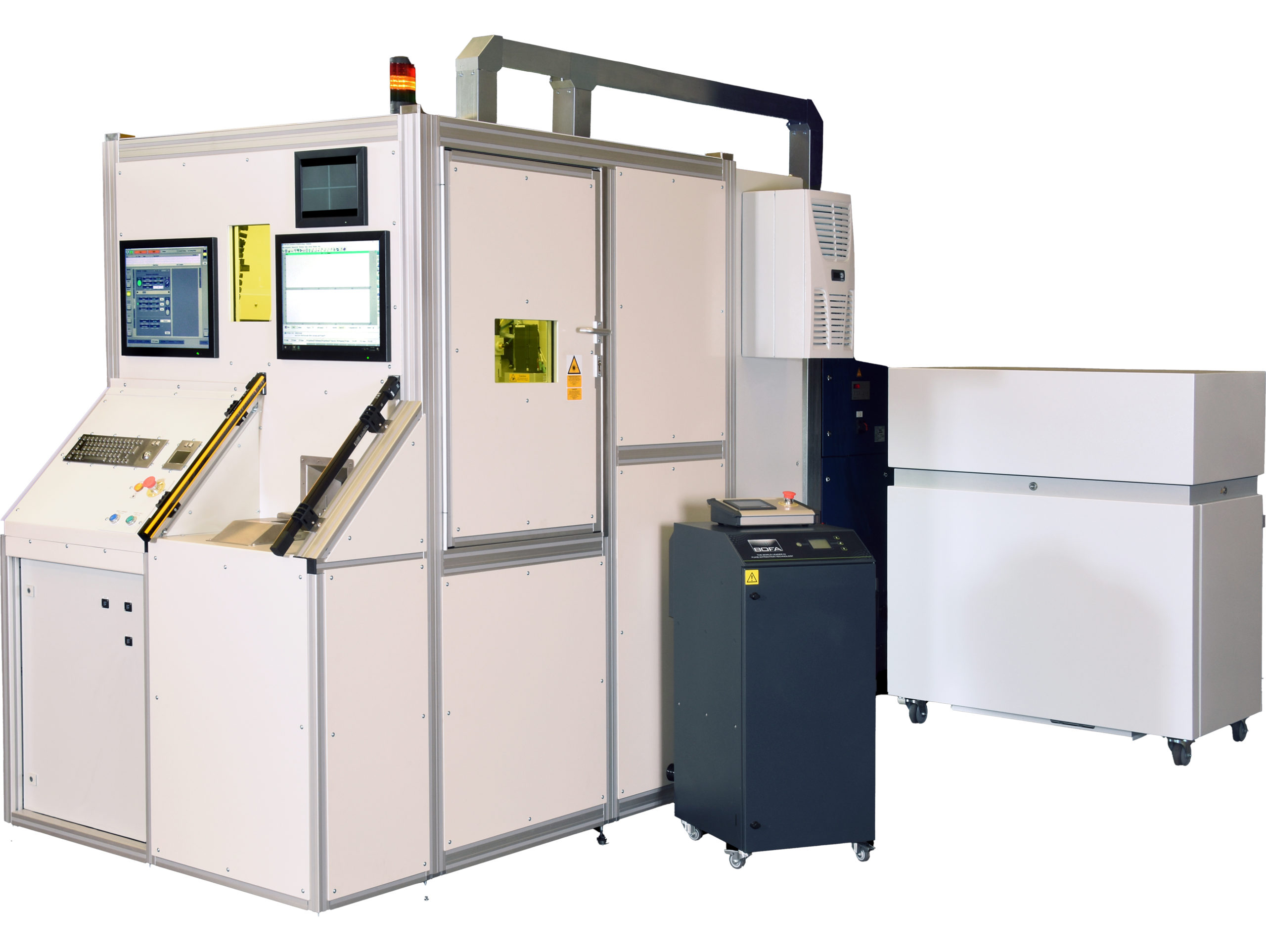

As part of the LBW equipment, we incorporate suitable extraction systems; and compared with electron beam welding, there are no x-rays produced, so it does not require an expensive vacuum chamber.

This also means that productivity can be high, especially where one source delivers multiple beams.

Our machines perform the weld in a protective atmosphere and include a complete work handling package. We can also set up the machine to make the process fully automated.

We offer a variety of laser, optics, and welding heads.

Conventional laser beam welding is a process that typically occurs at atmospheric pressure, using a shielding gas.

Shield gasses are consumable and are often necessary to protect the weld area from oxygen and water vapour.

As part of the LBW equipment, we incorporate suitable extraction systems; and compared with electron beam welding, there are no x-rays produced, so it does not require an expensive vacuum chamber.

This also means that productivity can be high, especially where one source delivers multiple beams.

Our machines perform the weld in a protective atmosphere and include a complete work handling package. We can also set up the machine to make the process fully automated.

We offer a variety of laser, optics, and welding heads.