Innovative Laser in Vacuum Window Protection Solution

Innovative Laser in Vacuum Window Protection Solution

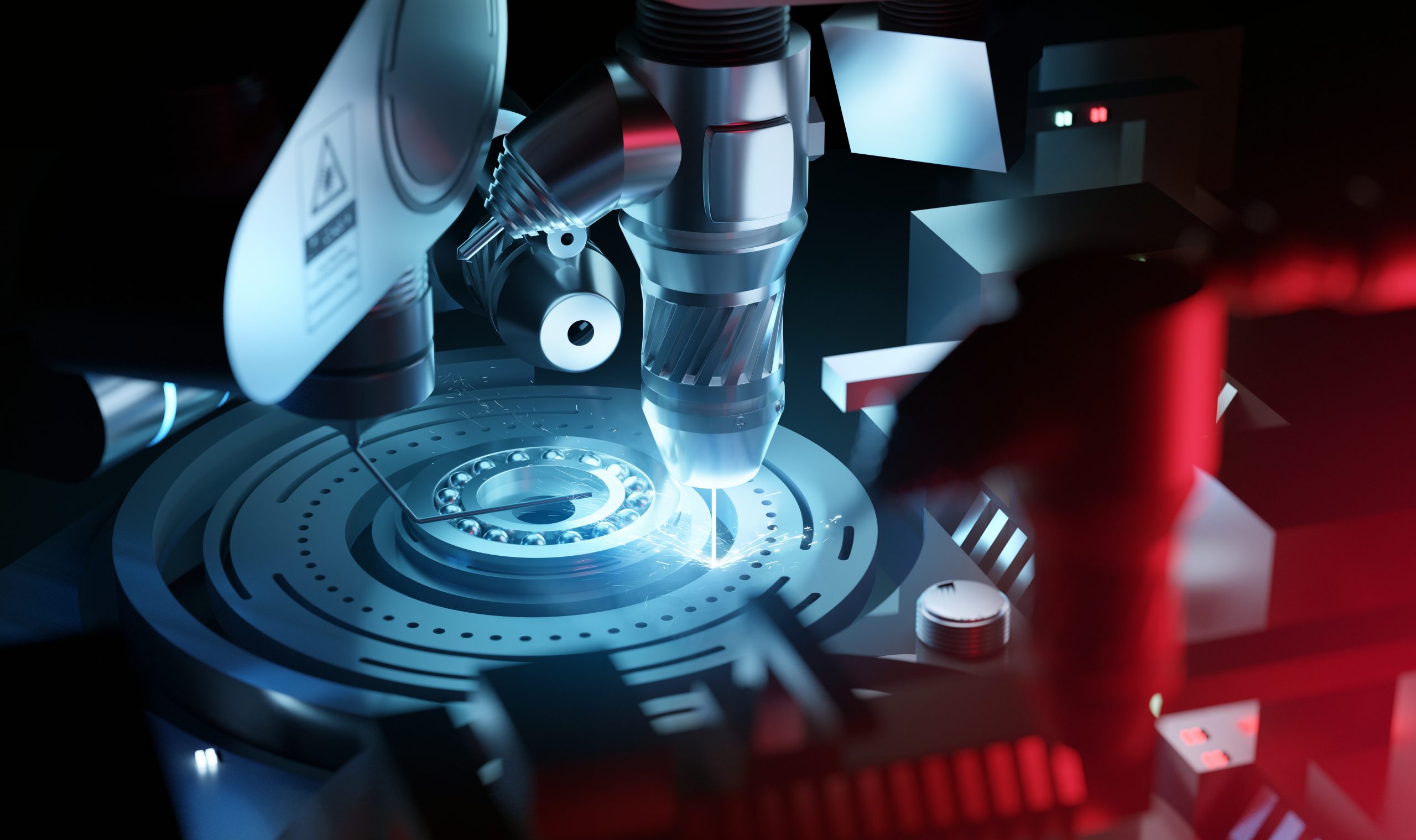

Laser welding in a vacuum is an excellent process that delivers deep and high-quality welds.

But laser coupling-in window contamination by welding vapour is a significant challenge facing the implementation of vacuum laser welding on a large scale.

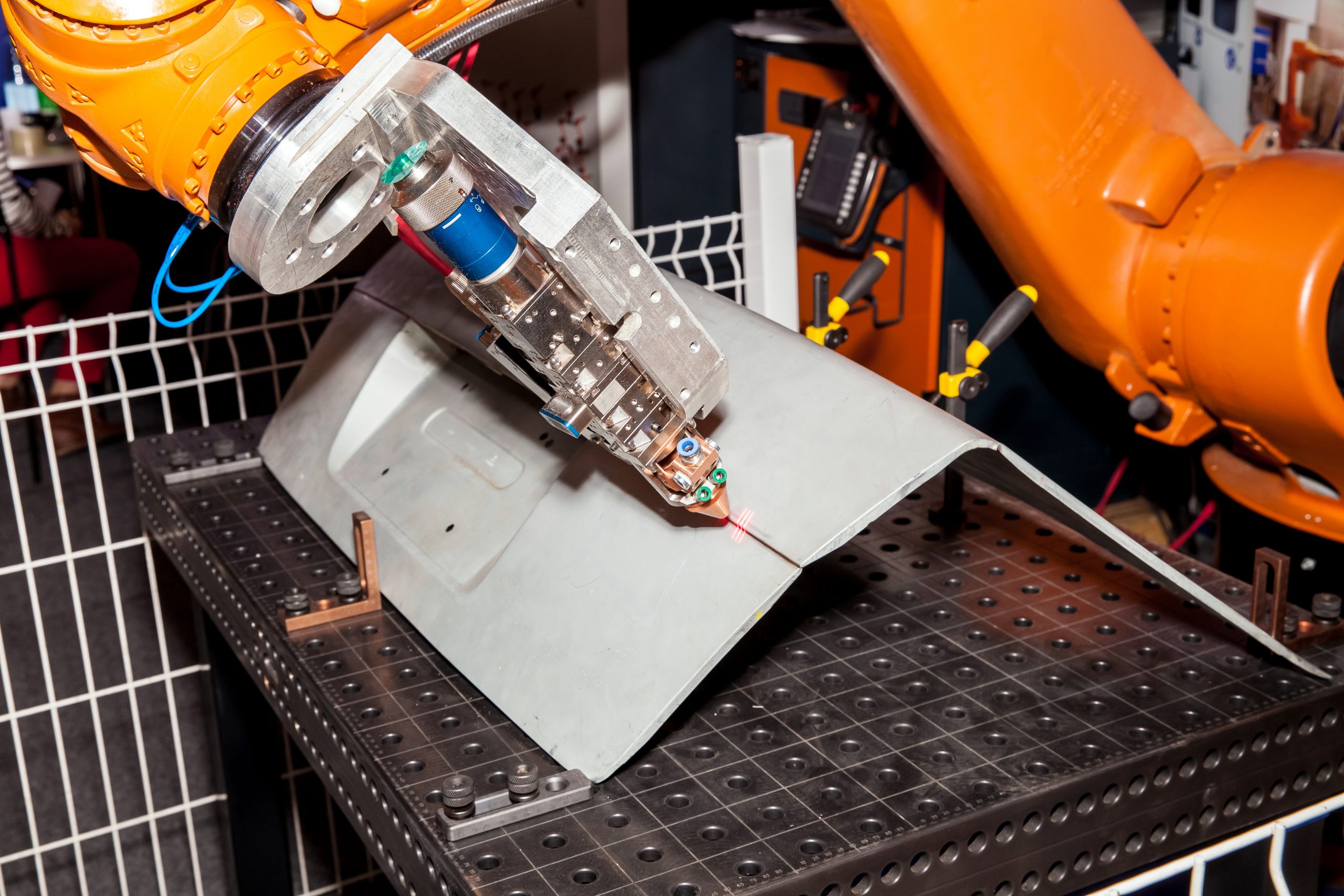

Through cutting-edge research in collaboration with Cranfield University, CVE has produced a window protection solution capable of operating effectively with very low levels of particulate generation.

Current Challenges

Many operators currently manage the window contamination problem by using a gas protection system. Operating at a low vacuum, this system uses a flow of gas to divert vapour away from the window.

However, low vacuum negates some of the advantages of vacuum. It causes the process emissions from welding to turn into a fine particulate that coats the chamber and workpiece.

This particulate is known as ‘soot’ and consists of a partially oxidised metal powder. A similar particulate also arises in atmospheric laser welding and is countered with a fume extraction system. In electron beam welding, the higher vacuum means the metal vapour can be deposited into an inert, solid, layer on the walls of the chamber.

In vacuum, proper soot extraction is a challenge due to the lack of atmosphere. The deposited powder is harmless in small quantities but begins to present a more significant risk when it builds into a thick layer. This can happen quickly when the machine is in heavy use. Airborne metal oxide powders can be toxic and present an explosion and fire risk. These risks are mitigated, but not avoided entirely, with regular cleaning. This conflict with health and safety requirements, as well as cleanliness standards, is unacceptable for many industries.

Figure 1. The soot deposited after 5 minutes of welding Ti64 using a low vacuum gas protection system.

Figure 2. The inert metal plating deposited after 3 hours of welding Ti64 using CVE’s innovative window protection solution.

A Ground-Breaking Solution

CVE’s work with Cranfield University has produced a window protection solution capable of operating effectively with very low levels of particulate generation.

This ensures cleanliness levels comparable with electron beam welding, while guaranteeing a long laser coupling-in window life. The low-cost consumable windows last for up to 3 hours of welding at low powers (3kW) with no appreciable weld degradation.

The rapid exchange system, also developed by CVE, allows window changes to be performed in seconds, keeping machine downtime to an absolute minimum.

These developments elevate the laser in vacuum process to the same level of reliability as the electron beam process and effectively eliminate the concern of optical contamination at low powers.

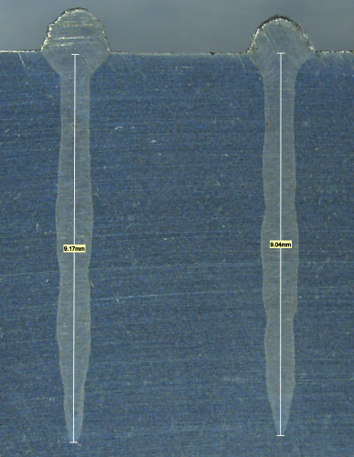

Figure 3. A comparison of a weld with a fresh window (left) and a window after 3 hours of welding using CVE’s window protection system. Protection is so effective that the window suffers virtually no degradation in this time.

Unleashing Potential

With this barrier removed, the potential of laser in vacuum can be fully realised as an alternative to electron beam, equal in quality, similar in cost and with key advantages depending on application.

Likewise, the quality superiority of vacuum laser over standard atmospheric laser can make an upgrade to a vacuum system very worthwhile.