Electron Beam Welding of Turbochargers

Introduction

With increasing legislation demanding cleaner engines and higher fuel efficiency, manufacturers equip modern passenger car and commercial vehicle engines with turbochargers.

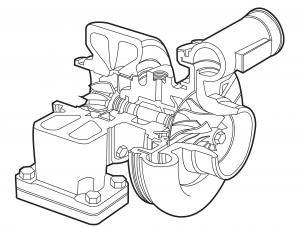

Figure 1. Turbocharger drawing.

Inertia Friction Welding

Automotive manufacturers previously used inertia friction welding to join the investment cast, Inconel wheel to the low alloy carbon steel shaft.

Although this produced a joint of adequate strength, the post-weld machining, grinding, and heat treatment operations were expensive and time-consuming.

Many leading turbocharger manufacturers have adopted an alternative welding process using electron beam welding (EBW).

EB Solution and Process Advantages

The process uses an electron beam that joins parts with high precision, significantly reducing the post-weld machining operations.

Consequently, because fewer machines are needed to produce a welded part, the investment cost of the manufacturing cell is reduced.

The welding process can be fully automated, and weld parameters, such as accelerating voltage, beam current, beam focus and traverse speed, are controlled. The high heat intensity produces a narrow fusion zone with very little distortion, so it is possible to weld together machined components in the finished or semi-finished condition.

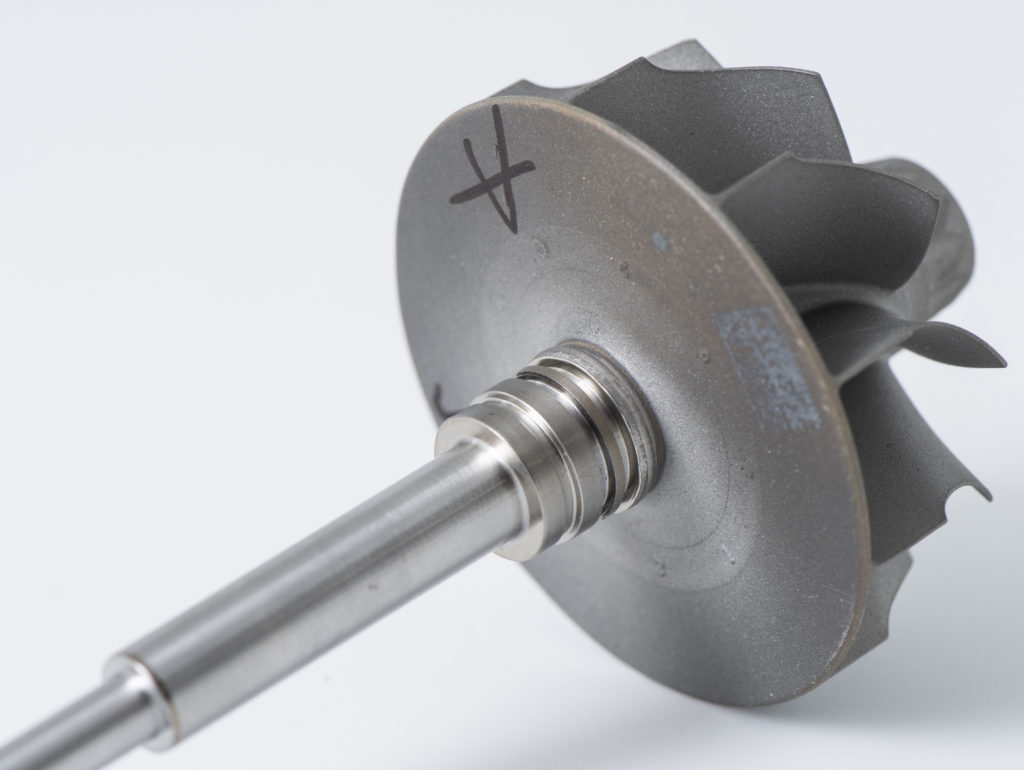

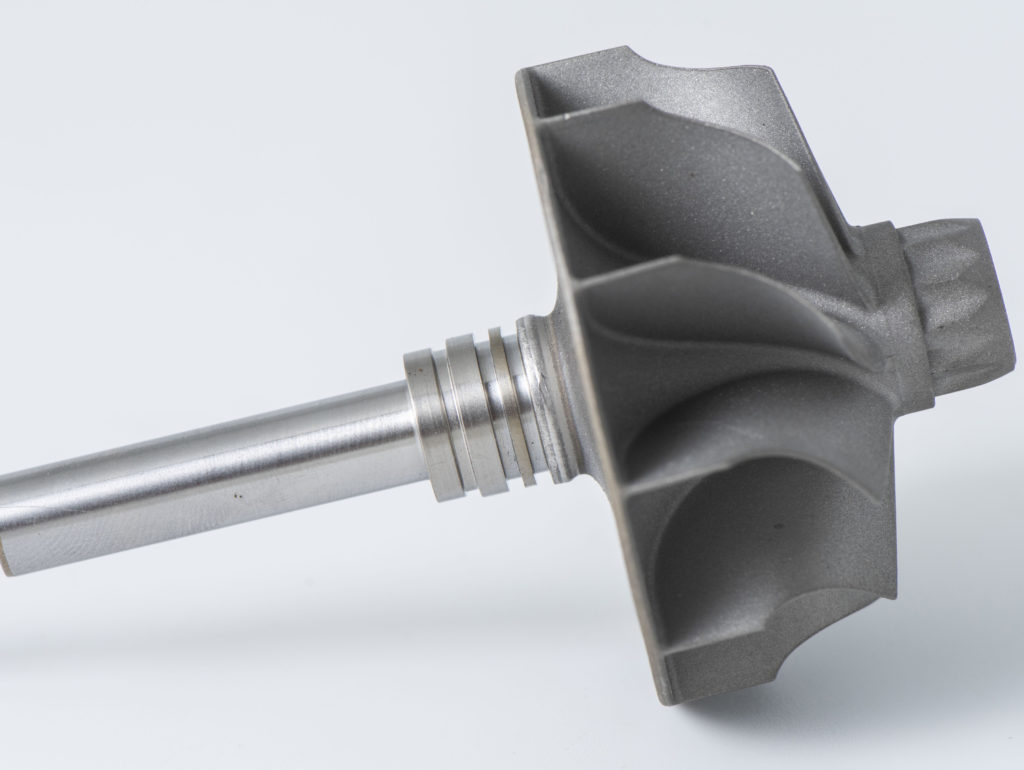

Figures 2 and 3. Turbocharger shaft and wheel.

Future Developments

In addition to electron beam welding shafts and wheels, you can also apply the process to other applications in turbocharger technology, including variable geometry turbos and wastegate valves.

CVE has supplied around 100 turbocharger welding systems throughout the world. And the adoption of electron beam technology seems set to continue.

Download CVE’s technical datasheet with information on our turbocharger electron beam welding machines.

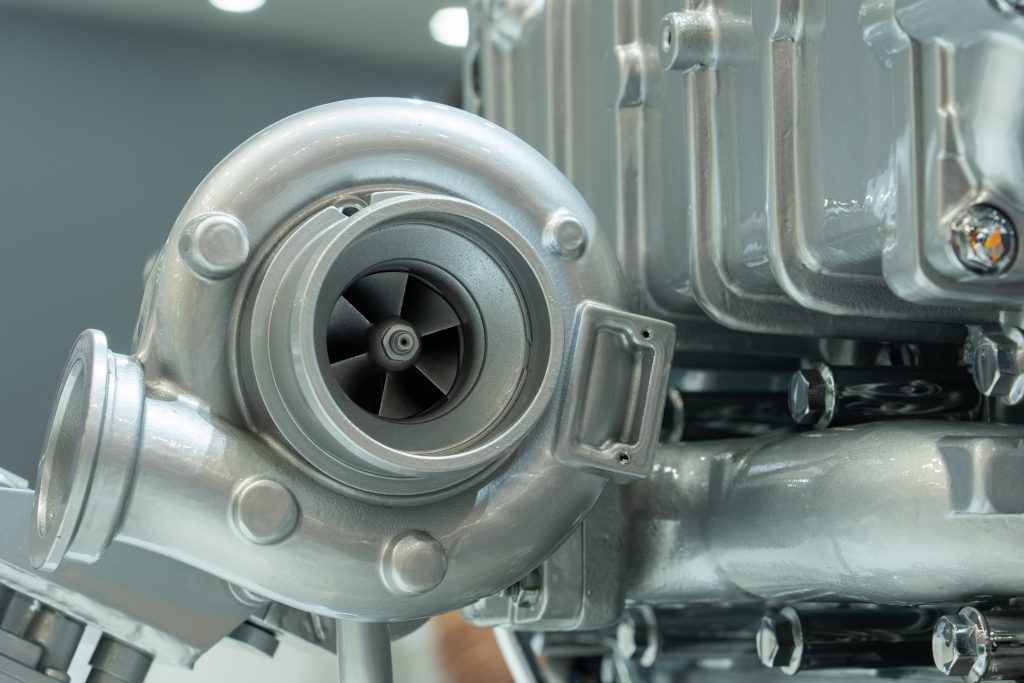

Figure 4. Close-up of diesel engine turbocharger.

Figure 5. Turbocharger structure with cross-section.