Electron Beam vs Laser Welding

Electron Beam vs Laser Welding Explained

Electron beam welding (EBW) and laser beam welding (LBW) fall under the same category of power beam welding. Despite this, there are some fundamental variations between each welding process and its applications. This article, electron beam vs laser welding, will explore the similarities and differences between electron beam welding in a vacuum and laser welding with a shielding gas – helping you decide which welding machine is most suitable for your application.

Overview

- What is the difference between electron beam and laser welding?

- Vacuum environment

- Shielding gas

- Component size

- Welding speed

- Weld quality

- Single pass welding of thick sections

- Automated process

- Wearing components

- Power efficiency

- Cost comparison

- Turnkey solutions

What is the Difference Between Electron Beam and Laser Welding?

EB welding uses a finely focused stream or beam of electrons, whereas laser welding uses monochromatic coherent light (photons). In both cases, the kinetic energy of the electrons or photons is turned into heat energy when they hit the surface of the metal.

Electron beam welding is lesser-known than laser welding out of the two techniques. And this is not because it is inferior to laser but mostly because of people’s perceptions. Many have seen Star Wars, James Bond, and a host of other hi-tech sci-fi films that have been present on our screens over many years. Culture, coupled with the high profile many respected institutions have been putting forward, has unfortunately meant that the electron beam process has taken a back seat.

Vacuum Environment

EBW takes place in a vacuum chamber. This aids the weld quality, as it tends to pull contamination away from the weld pool. Welding in a vacuum also results in the operator not becoming exposed to the hazardous welding environment.

Conventional laser welding takes place at atmospheric pressure, with additional shielding gas. However, you can laser weld in a vacuum, which significantly increases the depth of the weld.

Shielding Gas

Shielding gas is not required for electron beam welding as the process takes place in either a low or high vacuum.

Laser welding at atmospheric pressure requires a shielding gas; it is an expensive but essential consumable. Fume extraction may also be an issue.

Component Size

The vacuum chamber on an electron beam welder restricts the component size, as parts must fit within it. Chamber volumes are kept to a minimum to reduce evacuation times.

Laser welding with a shielding gas can accommodate any component size, as there is no vacuum chamber. Furthermore, you can use fibre optic delivery systems. This allows the welding head to be remote from the power source.

Welding Speed

Electron beam welding can achieve deep penetration welds over a wide range of speeds, whereas laser welding with a shielding gas always requires high welding speeds due to the plume of metal vapour that forms.

Weld Quality

Electron beam welding produces high-quality weld joints in a wide variety due to the inert atmosphere, which creates a very stable and repeatable environment. Joint finding and imaging using backscattered electrons are advanced options that can further increase the weld quality.

Laser welding needs a shielding gas, typically nitrogen or argon, to prevent oxidisation of the weld area and ensure the stability of the weld pools. Real-time monitoring of weld depth and quality are expensive options, but they can improve weld quality.

Single Pass Welding of Thick Sections

Electron beam welding in a vacuum can achieve 20mm penetration in stainless steel when using 6kW beam power at 60kV, achieving up to 300mm thicknesses can in a single pass.

Laser welding with shielding gas can achieve approximately 1kW per mm depth of weld in steel. However, limited availability and high cost of high-power laser systems is a factor.

Automated Process

Electron beam welding can be highly automated with the evacuation time of the chamber in a few seconds. A typical cycle time in the automotive industry is 40 seconds per component. But time is dependent upon the length and complexity of the weld.

Laser welding can also be highly automated with high production rates, in addition to there being no waiting time for chamber evacuation. Beam splitting and beam sharing are also possible.

Wearing Components

The main wearing component within the electron beam welding process is the filament. Metal vapours can deposit on the viewing prism, but this has no effect on weld characteristics, and you can clean the prism.

During laser welding, a metal vapour that the welding process produces can coat the optical devices such as mirrors and lenses, leading to a drop in beam power.

Power Efficiency

Electron beam welding is a very efficient process, typically converting 85% of electrical power.

Laser welding typically converts up to 40% when using modern fibre and disc lasers.

Cost Comparison

Electron beam welding is more expensive than Tungsten inert gas (TIG) and metal inert gas (MIG) welding.

Laser welding is also more expensive than TIG and MIG, with prices increasing steeply with increasing power.

Turnkey Solutions

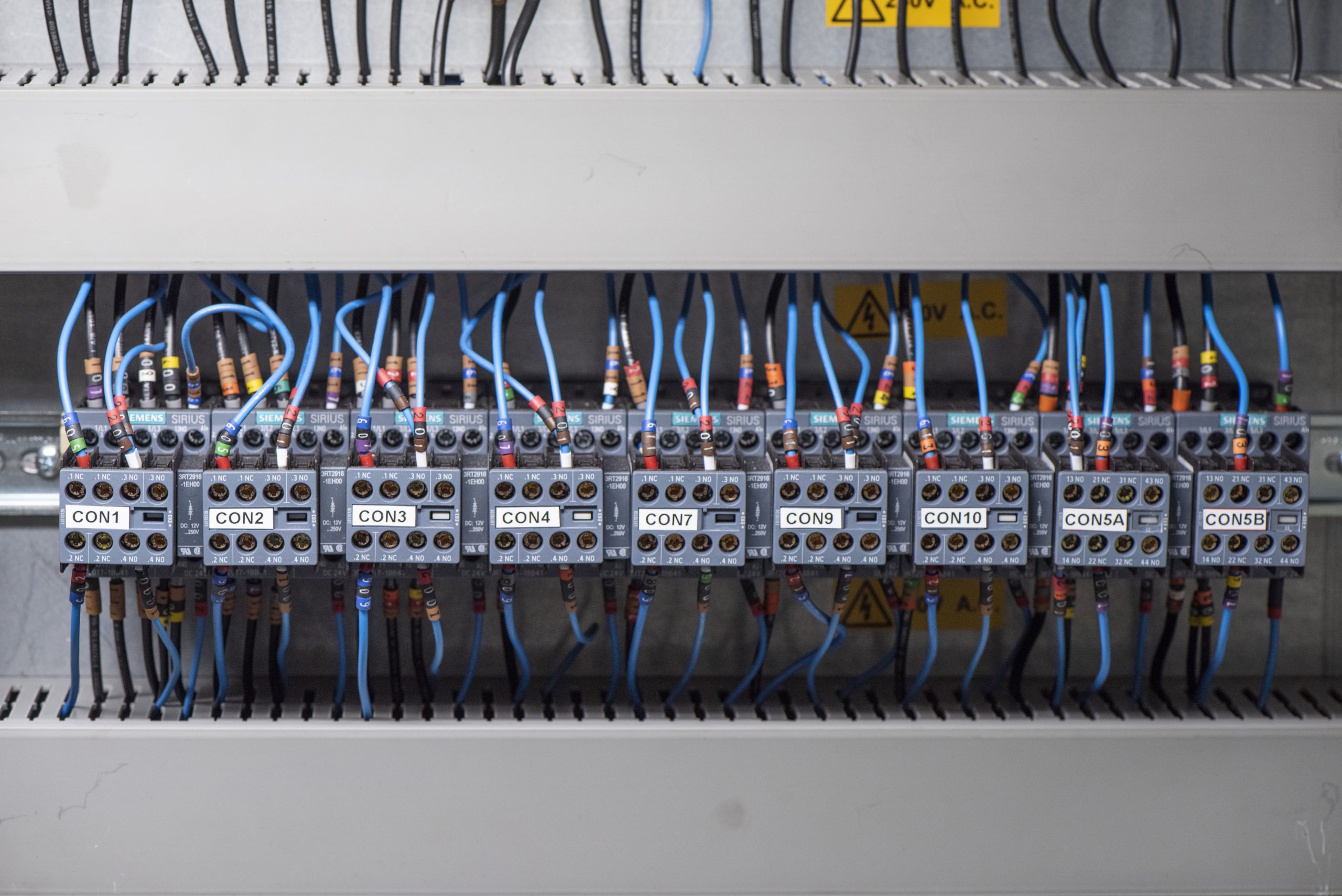

Electron beam systems include a chamber, fully automatic vacuum system, work handling, and control system.

Laser welding usually requires a systems integrator to provide an integrated solution, as the laser source does not include a control system or work manipulation.

Conclusion

The best process to use, electron beam vs laser welding, is often dependent on the given welding application. If you are not sure which system is best for your application, please get in touch! Our machines are built to order and manufactured at our Cambridge Headquarters. With 60-years of process know-how in providing turnkey solutions, we can find the right solution for your application.