Evflow: Making Stronger EV Connections

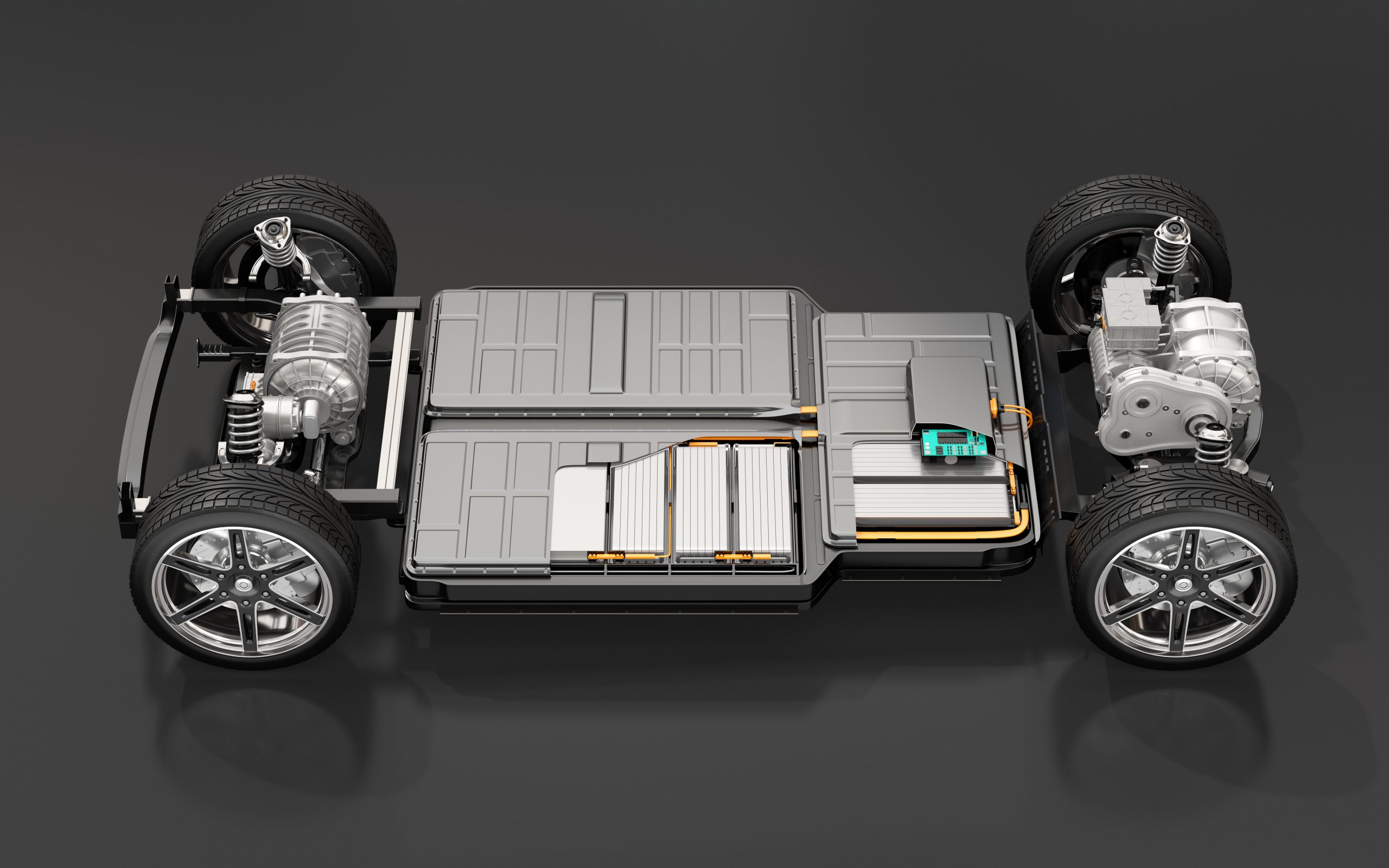

Evflow is an electron beam welding machine for producing electric vehicle (EV) power train components, including batteries, inverters, and motors.

Electron beam welding is an extremely consistent process, creating strong, high-quality welds.

It is significantly faster than laser welding for this application, as the beam can be deflected electromagnetically with no moving parts. This allows it to move at speeds faster than a mechanical laser mirror.

You can also change the focal point of the electron beam dynamically and rapidly using electromagnetic focusing coils. This allows the electron beam to process very wide areas without having to move the component or the weld head mechanically.

The focal depth of the electron beam is typically longer than a laser. This combined with the lack of issues with reflectivity, make electron beam welding a more reliable technology for mass production, as it has wider tolerance for part misalignment.

Furthermore, as there is no reflectivity from an electron beam on metals such as copper (unlike laser), there is a greater intensity of heat. As a result, less material is required in critical areas, such as hairpins, to absorb the heat.

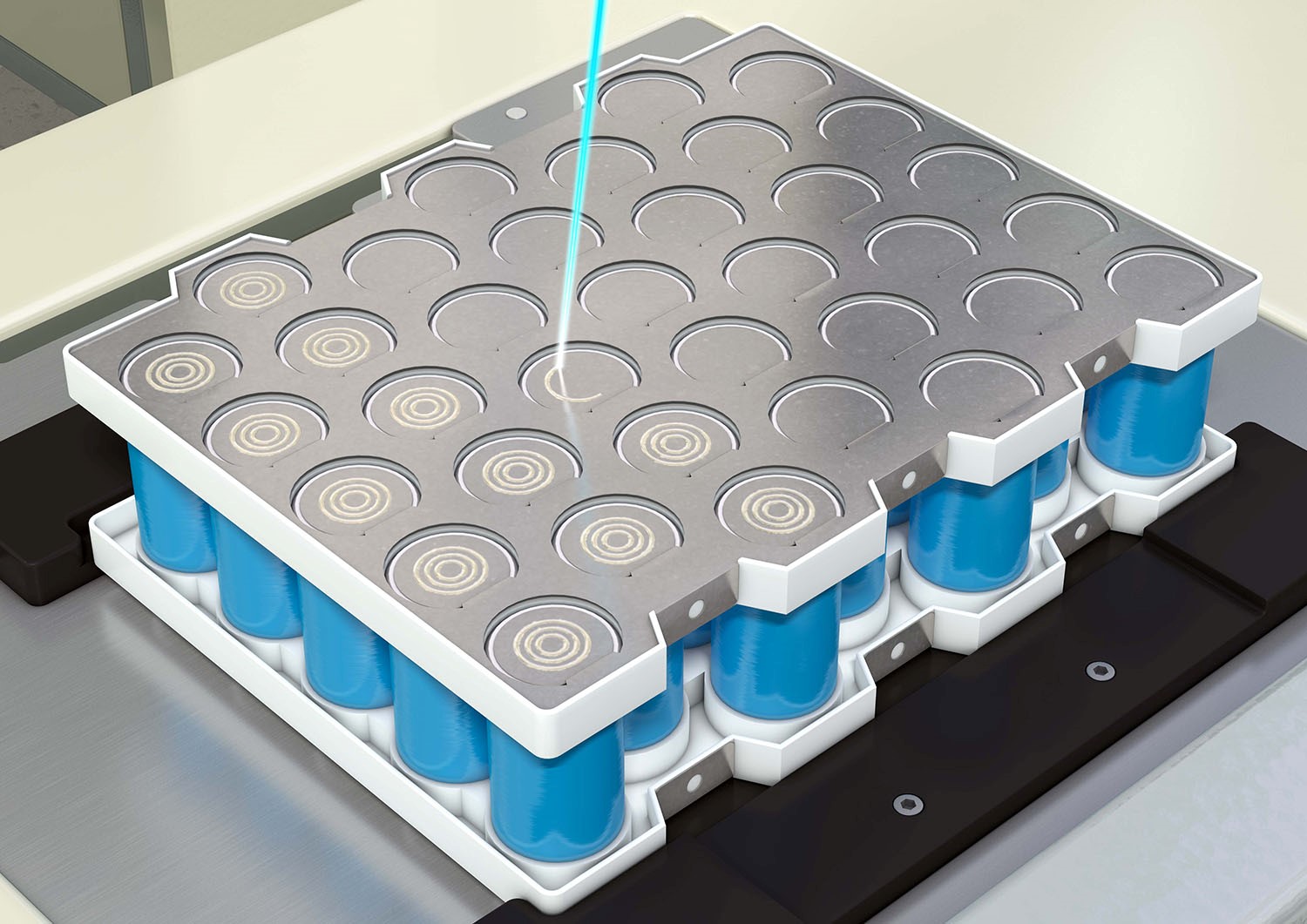

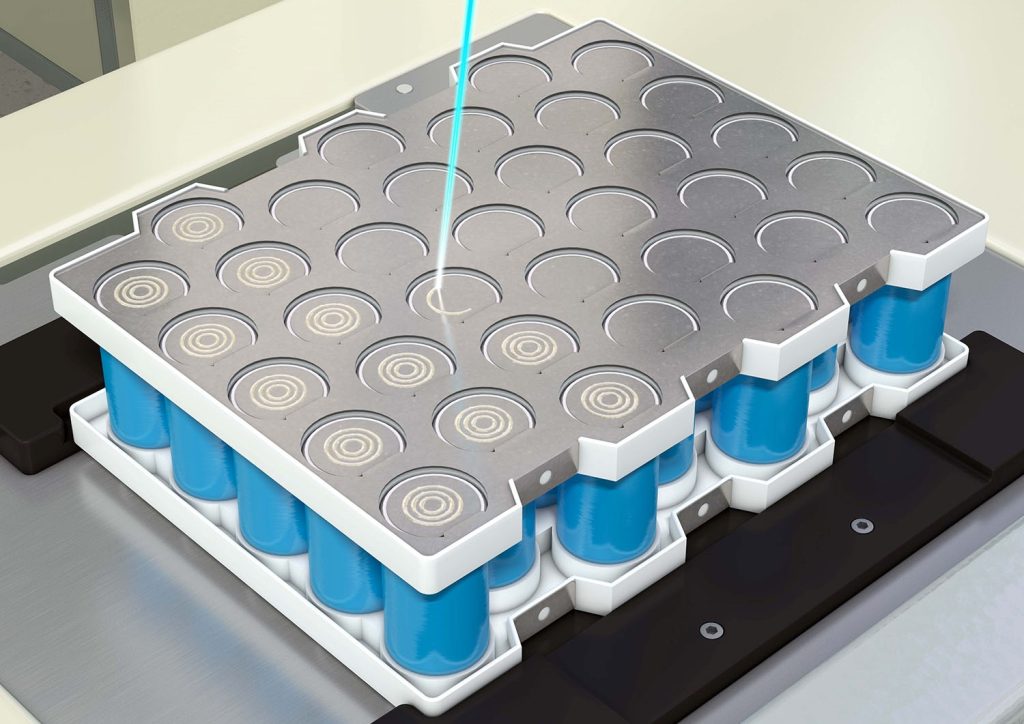

As the vacuum chamber contains the welding process, there is less spatter, so the welds are extremely consistent.

The vacuum also helps reduce the porosity in the weld, creating a better electrical connection and increasing the efficiency of the electric vehicle.

Find out more about the differences between electron beam and laser welding.

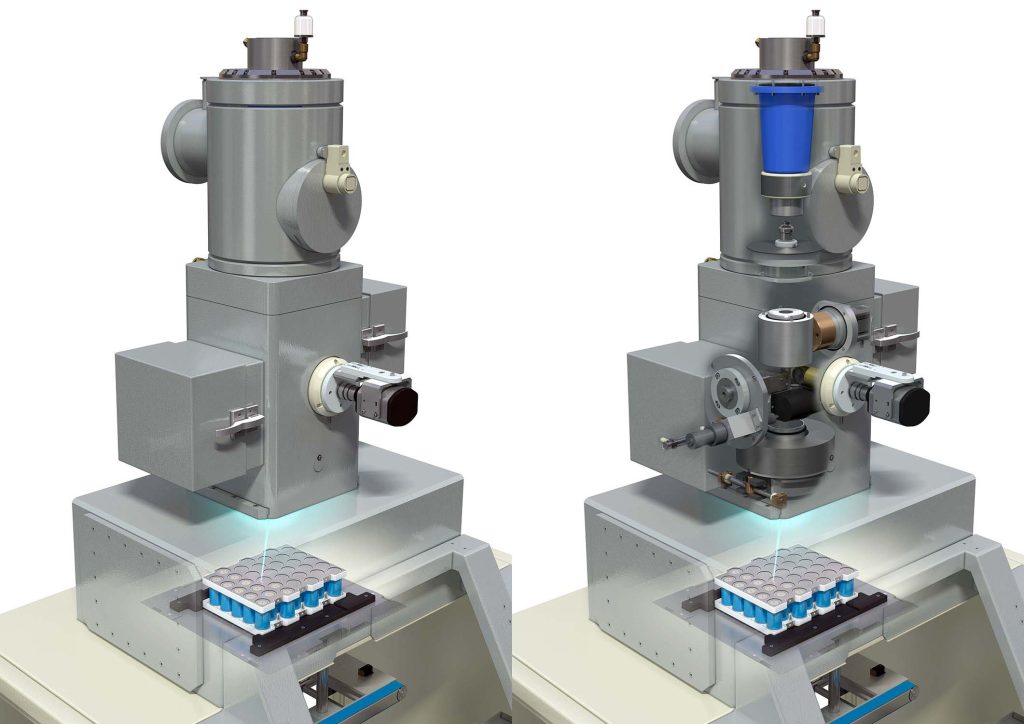

Production Evflow machine.

Busbar battery welding.

Producing EV Powertrain Components

Electron beam column

- High speed beam focus

- Dynamic gun column stigmator system

- Rapid wide range deflection

Electron beam column with rapid wide range deflection.

Typical Battery Weld Times

| Time to weld one cell (4 welds) | Time to manufacture one battery pack | |

| Typical for resistance welding | 4 seconds | 12,000 seconds |

| Typical for laser welding | 0.42 seconds | 1,260 seconds |

| Demonstrated speed for electron beam | 0.063 seconds | 189 seconds |

| Anticipated development for electron beam | 0.025 seconds | 75 seconds |

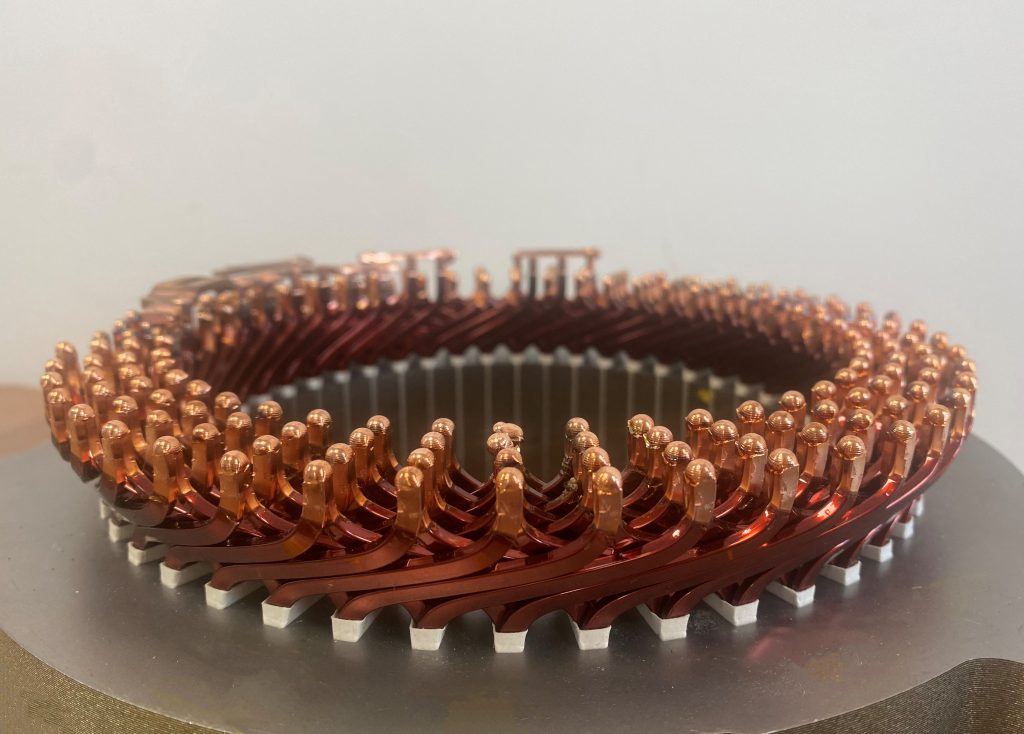

Motor stator welding.

Copper hairpin welding.

Machine Equipment, Features, and Options

Standard Equipment

- Function generator for application of welding patterns

- Directly heated cathode

- Separately pumped gun column (turbo-molecular)

- Filament alignment jig

- High-quality HDMI camera, with adjustable cross hairs and video capability

- Industrial PLC

- Fully automated vacuum system

- PC-based HMI, with recipe storage and data logging

- eWon ethernet hub for remote diagnostics

- Air-conditioned electrical cabinet

Tooling Options

- Custom tooling

- Indexing carousel

- Motorised gun-slide

- XY table

Advanced Features

- Automatic focus and alignment

- Automatic joint finder and imaging using back scattered electrons

- CNC control

- Dry vacuum pumps

- Mylar film protector

- Recirculating water chiller

- Special beam functions, including beam splitting

- High speed beam focus

- Dynamic gun column stigmator system

- Rapid wide range deflection

- Reduced power input