Forum for Engineering Structural Integrity

Forum for Engineering Structural Integrity

This week, CVE attended the 17th Engineering Structural Integrity Assessment Conference (ESIA17) between the 23-25 May 2023. The conference was in conjunction with the China Structural Integrity Consortium’s International Symposium on Structural Integrity (ISSI 2023).

The conference, which took place at The Lowry in the heart of Greater Manchester, provided a unique opportunity for the engineering structural integrity community to learn about novel solutions and technical advances to some of the most urgent challenges facing engineering today, and to network with leaders in ESI from around the world.

Renewables

Chris Punshon, CVE’s Head of New Energy Applications, presented on the suitability of electron beam welds for the fabrication of wind turbine sub structures.

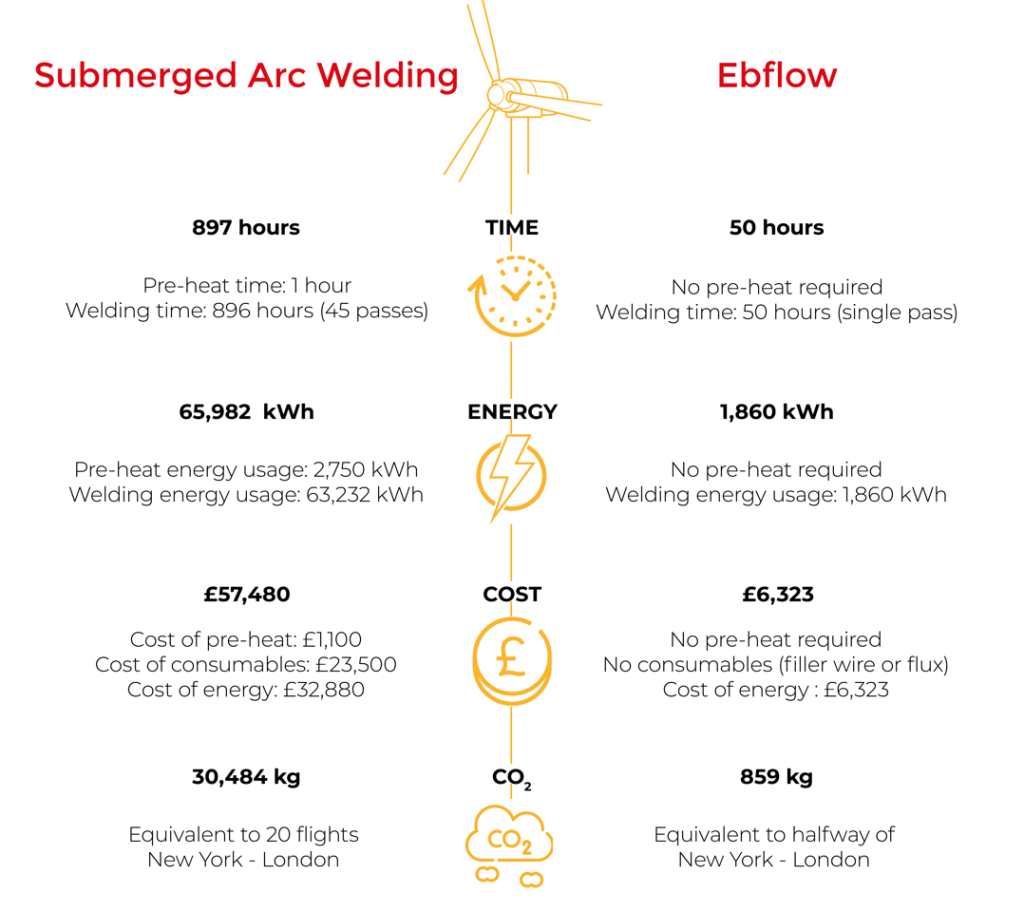

Wind turbine structures are made from thick carbon steel (typically grade S355) plates. The thickness makes submerged arc welding the default choice by manufacturers.

However, submerged arc welding requires preheat, a significant quantify of welding consumable, and the multiple passes mean welding is time consuming.

Electron beam welding is an alternative welding technique, which has the potential to significantly reduce welding time. Steel of up to 200mm thick can be welded in a single pass, and a longitudinal seam weld in a monopile can be produced in minutes rather than hours.

A key step in enabling fabricators to implement electron beam welding is to confirm that the mechanical properties and fatigue performance are suitable.

The presentation presented the key similarities and differences between electron beam welds and conventional arc welds, including a discussion of the most appropriate way to test electron beam welds in order to obtain a reasonable measure of fracture toughness.

For more information, please get in touch.