Italian Leaders in Electron Beam Welding

Introduction

Celsia is based near Lake Maggiore, in the Verbania area of northern Italy, situated between Milan and the Swiss border (specifically in Anzola d’Ossola).

Established in 1963 by Silvio Tedeschi and Antonio Bionda, the production plant started out as a manufacturer of low-voltage electrical contacts, aided by the know-how and the technology of its associated company, FILMS.

Towards the end of the 1960s, Celsia began producing composite materials made through infiltration (silver/tungsten and copper/tungsten), both for the electrical and electro-mechanic sectors.

Production Plant

Today, the ISO 9001 and ISO 14001 certified production plant has a range of tungsten-based sinters, brazing alloys and electrical contacts for medium and high voltage applications; the plant supplies some very high-profile clients, including ABB, Schneider, Siemens, Luxottica, Gerdau and Toshiba, amongst others.

In terms of sintered parts, the plant manufactures electrodes for the production of electro-welded wire mesh, electrodes for diamond tools sharpening, and electrodes for EDM die-sinking machines.

With regard to electrical contacts, the Celsia range includes electrical contacts for medium and high voltage switches and electrical contacts for medium and high voltage disconnecting devices.

Finally, for brazing alloys, the products on offer supply the goldsmith, glasses-making, clock-making and precision mechanics industries.

Electron Beam Welding

In its production, Celsia employs, as well as silvering and copper plating (a process through which items or components are coated with a thin metallic layer), electron beam welding (EBW), a fusion welding technology in which an electron beam hits at high speed the surface of the welding pieces and penetrates into their material.

The kinetic energy of electrons is transformed into thermal energy, which can be used for materials processing. The electrons are emitted by a heated gun. A vacuum must be produced and maintained in the entire beam generator area and in the working chamber in order to avoid too strong a divergence of the electron beam caused by the collision of the electrons with the air molecules.

The high energy concentration in the focal point of the electron beam results in a very high power density (the power density is 100 to 1000 times higher than in arc welding methods) and means it is possible to weld different materials with each other. Furthermore, the electron beam is, by means of the electromagnetic fields, deflected almost without inertia, which leads to the generation of extremely high-frequency oscillation movements entailing different welding advantages.

Through the high power density of the electron beam the energy input into the part is relatively low, which leads to almost distortion-free joining of finished products.

Cambridge Vacuum Engineering

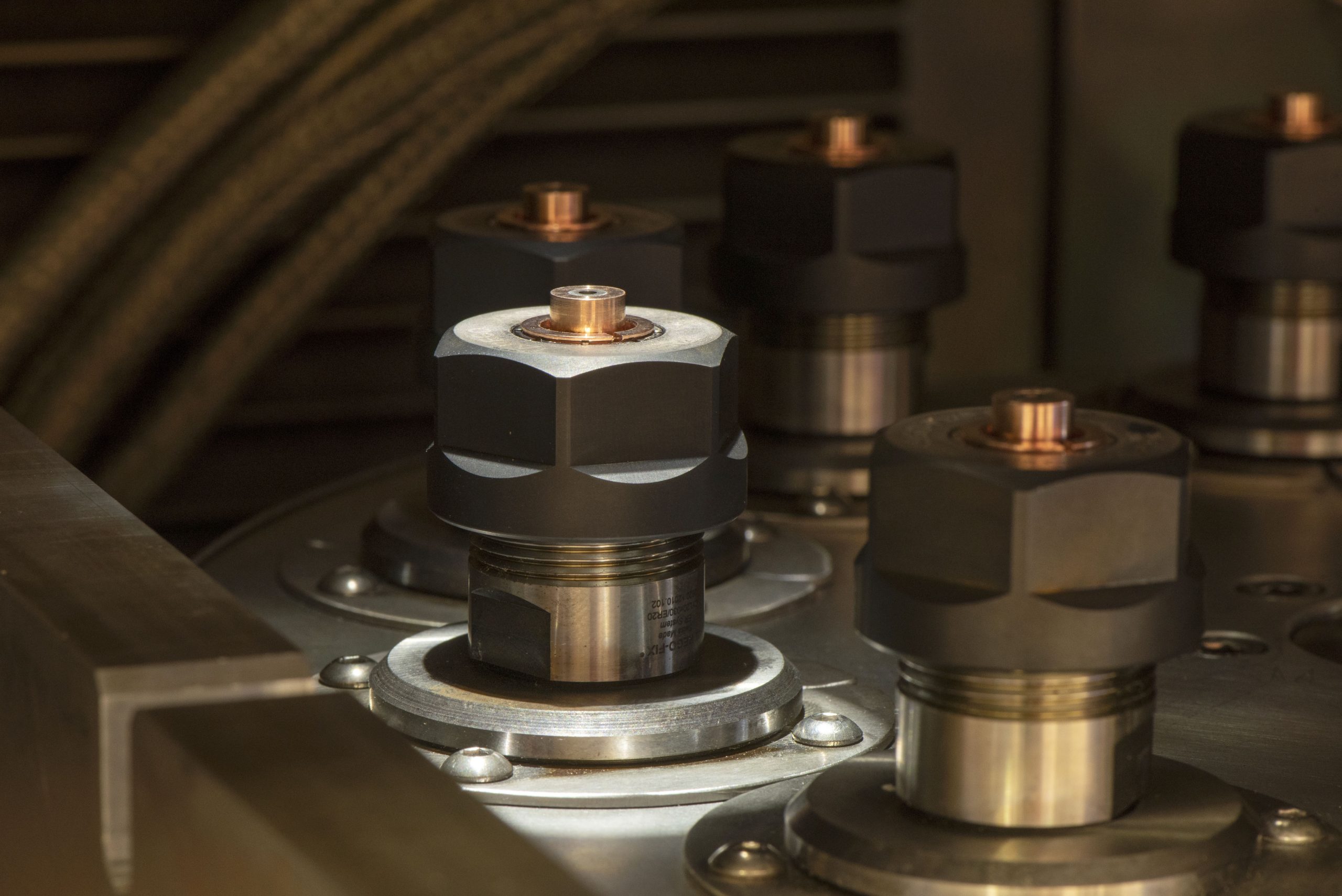

The CVE Model CW60.15 recently purchased by Celsia has some outstanding features, including a 60 kV electron gun with a turbo-molecular pumping system, a filament alignment jig for accurate and repeatable filament change, a 15 kW switch mode power supply and beam deflection. Furthermore, it also boasts a focus and function generator, a 450 mm cube chamber and an enhanced fully automatic pumping system for operating in the 10-4 mbar range.

The machine has two separate pumping systems for the work chamber and the electron gun. The chamber can operate in either high vacuum (10-4 mbar range) or low vacuum (10-2 mbar range). Another feature is that an isolating valve is incorporated in the gun column so that the gun is maintained at high vacuum when the chamber is vented. This model enables the welding of materials with a thickness of up to 40 mm. Moreover, the distance between the welding gun and the work-piece (the stand-off distance) can reach 70 cm.

Figure 1. CVE model CW 60.15

Article courtesy of OMCD Group. Published 23 February 2017. https://www.omcd.it/italian-leaders-in-electron-beam-welding/.