An Introduction to Electron Beam Welding

How Does Electron Beam Welding Work?

Electron beam welding works by generating high power electron beams that pass through an anode onto the workpiece.

Overview

- What is electron beam welding?

- How does electron beam welding work?

- Components of an electron gun

- How is the electron beam generated?

- How is the electron beam controlled?

- Electron beam welding machine schematic diagram

What is Electron Beam Welding?

Electron beam welding (EBW) is a fusion welding process that uses a high energy electron beam to join metals together, with a wide range of applications in many industries.

How Does Electron Beam Welding Work?

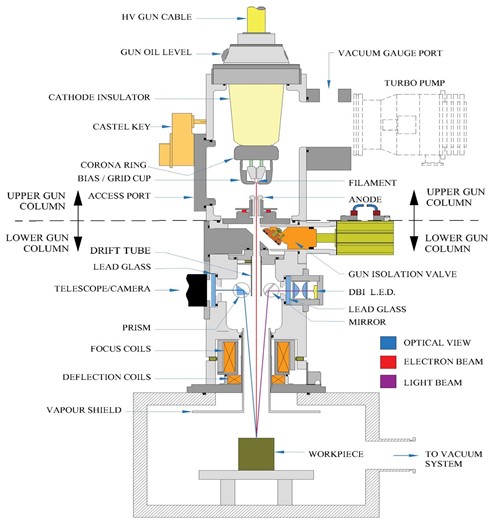

An electron beam welding machine consists of an electron gun, which is a device for producing a focused beam of high-speed electrons with velocities of between 0.3 and 0.7 times the speed of light.

The electron gun is normally mounted on, or in, a high vacuum chamber that contains tooling used for holding and moving a workpiece.

The electron beam passes through the anode and on towards the workpiece, using a focusing lens to focus the beam and achieve sufficient power density to weld the two metals.

This creates a high weld quality, with deep penetration and a narrow fusion zone.

Components of an Electron Gun

An electron beam is usually formed by employing a triode-style electron gun that consists of:

- A cathode (also known as a filament)

- A heated source (emitter) of electrons that is maintained at a high negative potential

- A grid cup (also known as a bias cup)

- A specially shaped electrode that can be negatively biased to the hot cathode emitter

- An anode, a ground potential electrode through which the electron flow passes in the form of a collimated beam

How is the electron beam generated?

The hot cathode, or filament, is made from a high emission material such as tungsten or tantalum, with tungsten being the most common. A heating current is passed through to a filament that causes it to emit electrons. These are accelerated from the filament to the anode by applying a high negative voltage to the filament.

How is the electron beam controlled?

A control electrode, or grid, is situated close to the filament and is held at a negative potential in respect to it. As the voltage potential between the filament and grid is reduced, electrons are allowed to escape. These are then attracted to the anode, which has more positive potential than the electrons, or in the case of electron beam welding, the anode has a hole in its centre which allows the electrons to pass through the anode as a stream, and on towards the workpiece.

As the electrons travel to the workpiece, they pass through a focus coil or focusing lens (electromagnetic lens) so that the beam can be focused to a fine point to achieve sufficient power density to weld metals. The electron beam will also pass through a deflection coil (electromagnetic) at the bottom of the column which can manipulate the beam at very high speeds.

The addition of some hardware enables functions such as backscattered imaging, joint finding, real-time seam tracking, automatic beam alignment, engraving, beam splitting and Surfi-Sculpt™*.

Electron Beam Welding Machine Schematic Diagram

Conclusion

Find out more about electron beam welding on our electron beam welding page, or watch our CGI animation video.

*Surfi-Sculpt is a trade mark of TWI Ltd.